Tips for Checking Free Weights

When inspecting free weights, make sure to check the:

You may have seen many explanatory articles introducing the use or selection of free weights. Today, as a senior free weight manufacturer, we will tell you how to easily check free weight products, so that you can avoid detours and buy really good fitness equipment.

Usually when we talk about free weights, we generally talk about four main categories:

1. Tips for Checking Barbell

2. Tips for Checking Dumbbells

4. Tips for Checking Kettlebells

1. Tips for Checking Barbell

Today we mainly talk about Olympic bars. Of course, barbells also include rubber-coated/PU integrated barbells and standard barbells (we will not talk about these two types today). The detection methods of rubber-coated/PU barbells can refer to rubber-coated/PU dumbbells (as follows article), while standard barbells generally only need to pay attention to: 1. Length and diameter; 2. Whether the electroplating surface is flat or not; 3. Whether the weight meets the standard. As for the load-bearing, there is generally no quantitative requirement (because standard barbells do not do heat treatment).

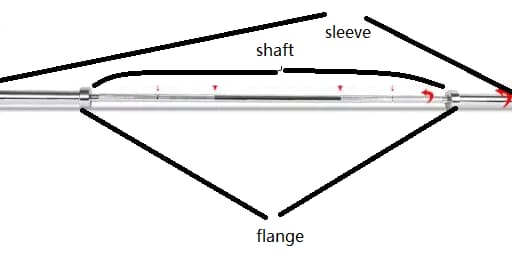

The Olympic bar is composed of a shaft, a flange and a sleeve, and the sleeve contains bearings, copper sleeves and circlips (However, due to the high requirements for the tester to remove the sleeve, today we will not talk about the detection of the inside of the sleeve), we can start from these places when we check the barbell:

(Find or make a picture similar to the picture below to mark the three key parts)

A. Shaft

The inspection of the shaft includes surface, diameter, straightness, yield test and load-bearing test. For materials, professional instruments (such as metallographic instruments) are required, which will not be introduced here.

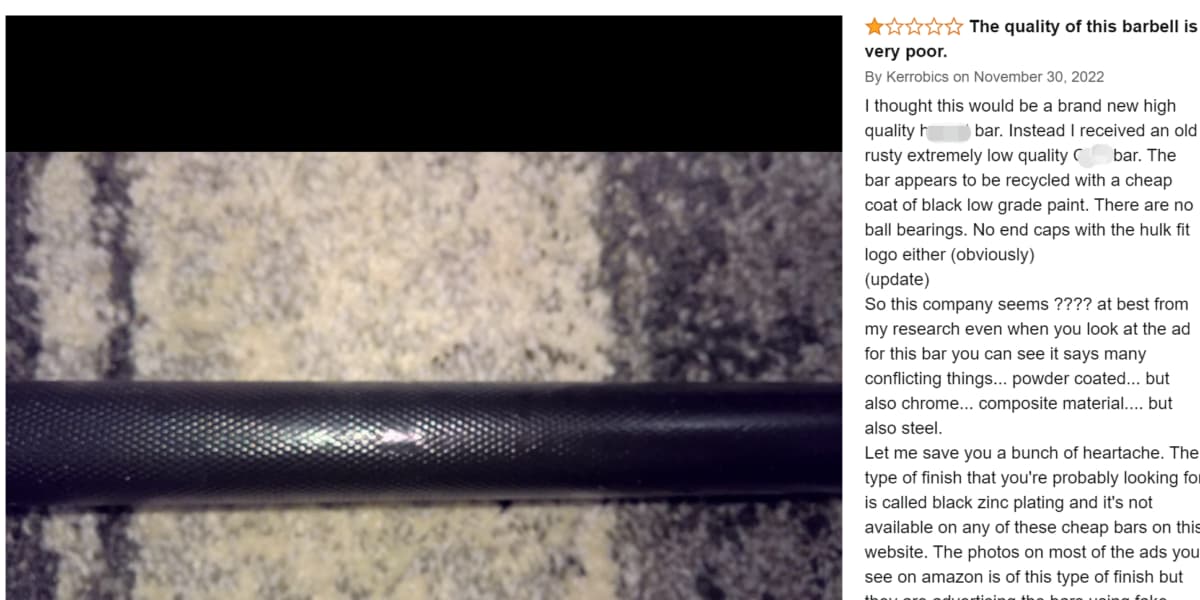

There are many options for the surface material of the Olympic shaft, including bare steel, electroplating (high brightness, high smoothness), hard chrome (darker color, high hardness), black chrome, phosphating black, oxide black, ceramics (with a blade There will be powder peeling off when scraping, high hardness), Teflon, stainless steel, etc., some materials are difficult to distinguish with the naked eye, you can send it to a professional organization for analysis, or send it to us for free testing.

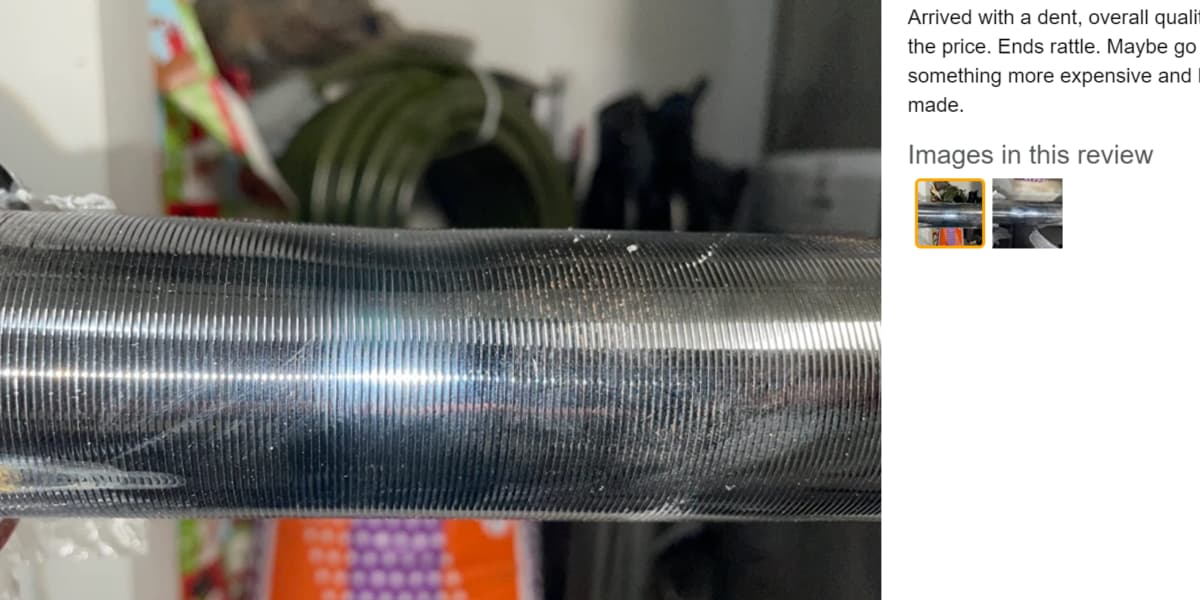

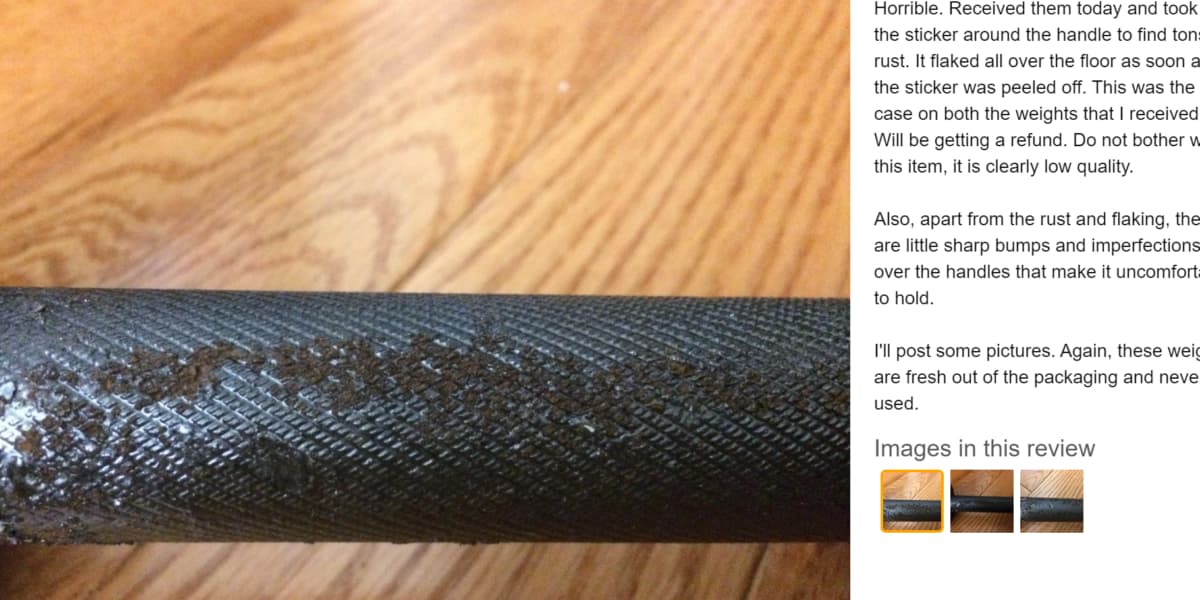

The following are the surface problems of Olympic bars produced by peers found on the Amazon website:

The following are the surface problems of Olympic bars produced by peers found on the Amazon website:

Diameter, the conventional diameter range is 28-29MM. Some organizations believe that 28MM is a weightlifting bar, 29MM is a power bar, and 28.5MM is a CROSSFIT. Of course, there are also unconventional ones.

Whip test is used to check the elasticity and recovery ability of Olympic bars. You can refer to the content starting at 2 minutes and 15 seconds of the following video:

After the whip test, it is generally necessary to arrange to check the straightness (with a straightener), and look at the deformation value.

The following are the straightness problems of Olympic bars produced by peers found on the Amazon website:

For the load-bearing test, you can hang pieces at both ends, use a forklift to fork up the Olympic bar, or use a hinge to pull up a heavy-weight Olympic bar at both ends to see the deformation.

(See if this picture can blur the non-test-related background to highlight the key points)

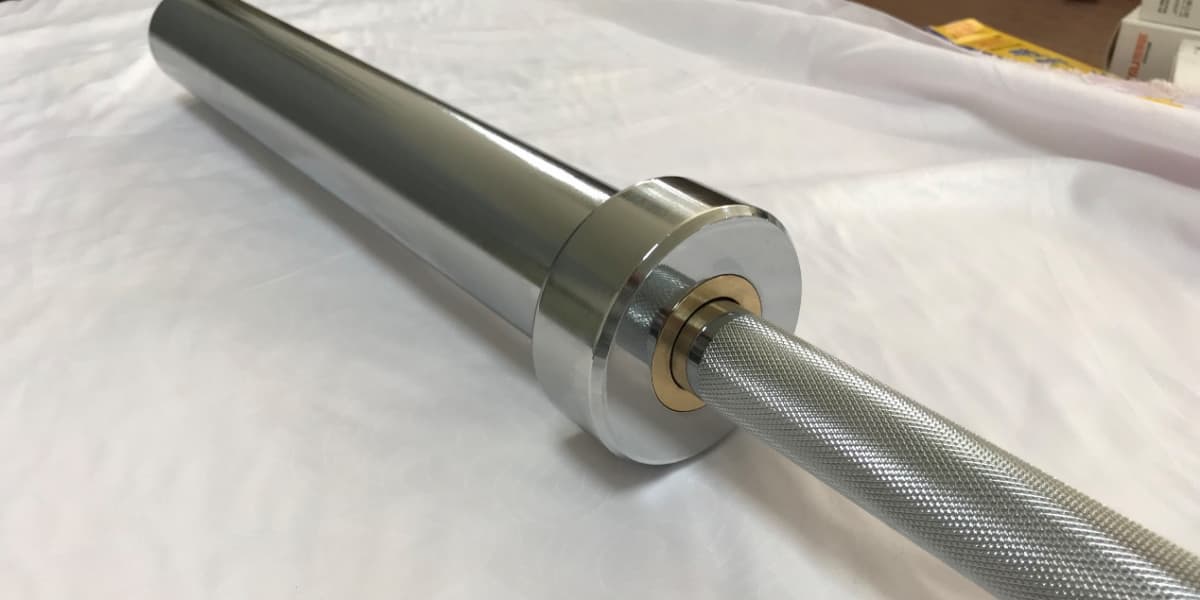

B. Sleeve

The inspection of the sleeve includes surface, diameter, smoothness, etc.

There are also many options for the surface of the sleeve, which is similar to the range of material options for the shaft, including bare steel, electroplating (high brightness, high smoothness).

There are also many options for the surface of the sleeve, which is similar to the range of material options for the shaft, including bare steel, electroplating (high brightness, high smoothness).

Hard chrome (darker color, high hardness)

Hard chrome (darker color, high hardness)

Black chrome

Phosphate black, oxide black

Ceramic

Ceramic

The powder will flake off when scraped with a blade, and the hardness is very high.

Teflon

stainless steel, etc.

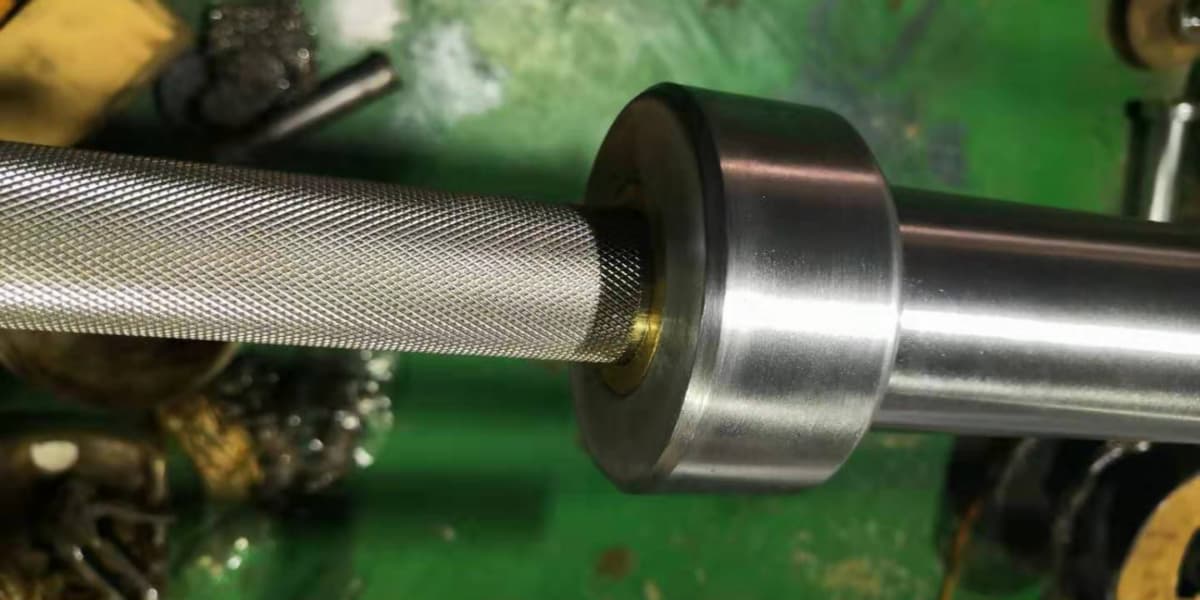

The sleeve diameter of the Olympic bar is generally 50MM, which matches the aperture of the Olympic barbell.

The sleeve diameter of the Olympic bar is generally 50MM, which matches the aperture of the Olympic barbell.

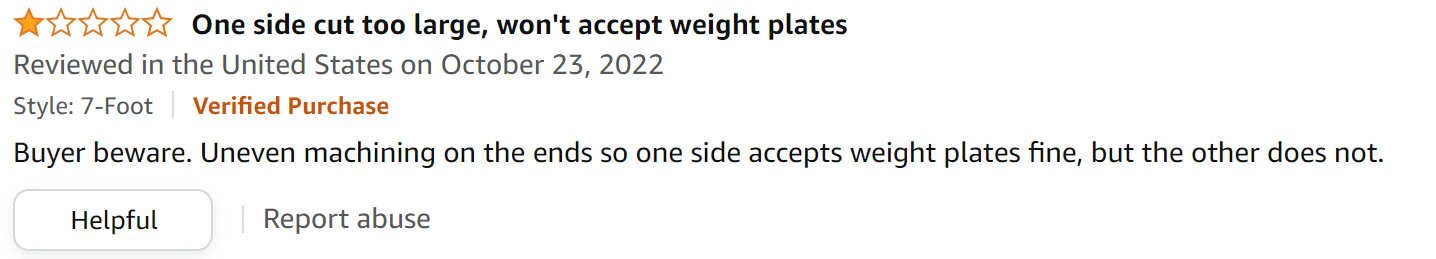

The following is the diameter problem of the Olympic bar socket produced by the peers found on the Amazon website:

Smoothness test, method can refer to the following video:

C. Weight

The weight is generally 20KG for men and 15KG for women. There are exceptions. For details, please refer to the following articles:

How Much does a Barbell Weigh?

D. Concentricity

Concentricity plays an extremely important role in the performance of Olympic bars. We have made a special video for this:

There are several ways to check the concentricity, such as the straightener mentioned above, in fact, you can simply check the concentricity without using heavy machinery and equipment, as shown in the following video:

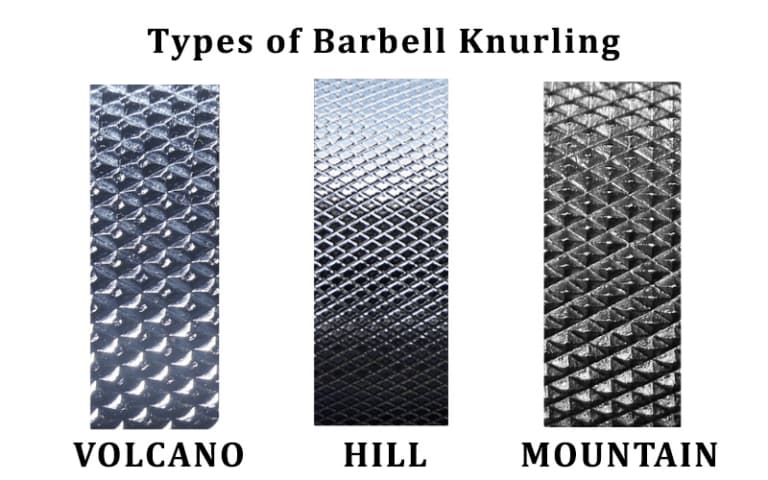

E. Knurling

Depth, interval, and knurling STYLE, and whether the knurling pitch setting conforms to IPF or IWF standards.

There are three types of knurling (for details, please refer to the article):

According to different customer requirements, the knurling depth is generally 0.8MM, 1.0MM, 1.2MM, 1.5MM. Generally speaking, the deeper the knurling, the stronger the friction. The deeper knurling depth is suitable for powerlifting and deadlifting. We call it “aggressive knurling”. On the contrary, the knurling is shallower, the grip will be more comfortable, and it is more friendly to the palm, but it is easy to slip.

Knurling problems of Olympic bars produced by peers found on the Amazon website:

If you have any questions about purchasing Olympic bars, you can refer to:

If you have any questions about purchasing Olympic bars, you can refer to:

2. Tips for Checking Dumbbells

The dumbbell is composed of two parts: the ball head and the handle. When we check the dumbbell, we can check the ball head and the handle separately:

A. Head

Ball head surface, shape, size, drop test, smell, label, hardness, etc.

surface

The surface material of the ball head includes dipping paint/painting/baking paint/powder spraying/electroplating/coating/dipping/TPU/CPU, etc.

Baking paint is actually just heating and drying after painting. Its paint fastness is relatively stronger. At present, most baking paints/spray paints on the market use hammer paint.

Pay special attention when inspecting dumbbells surface

-

1. Blistering phenomenon.

In the later stage, if it is crushed by external force, the original iron will be exposed.

-

2. Hanging paint phenomenon

Because the product has to be hung up to dry or dry after painting, and the paint is not dry at that time, so the liquid paint will flow down under the influence of gravity.

-

3. Paint peeling

Some are due to not spraying (such as the position of the lanyard), and some are caused by bumping, especially for heavy dumbbells. Workers can easily bump into the surface of the dumbbell during transfer.

-

4. Flashing phenomenon

Sometimes it is because the surface of the casting is not polished properly, or it may be due to the uneven process of the paint from wet to dry, or after drying/drying, the lanyard will be pulled out from the dumbbell to form a gully, even if it is repaired later. paint, it is also easy to produce flash, and even easy to hurt your hands

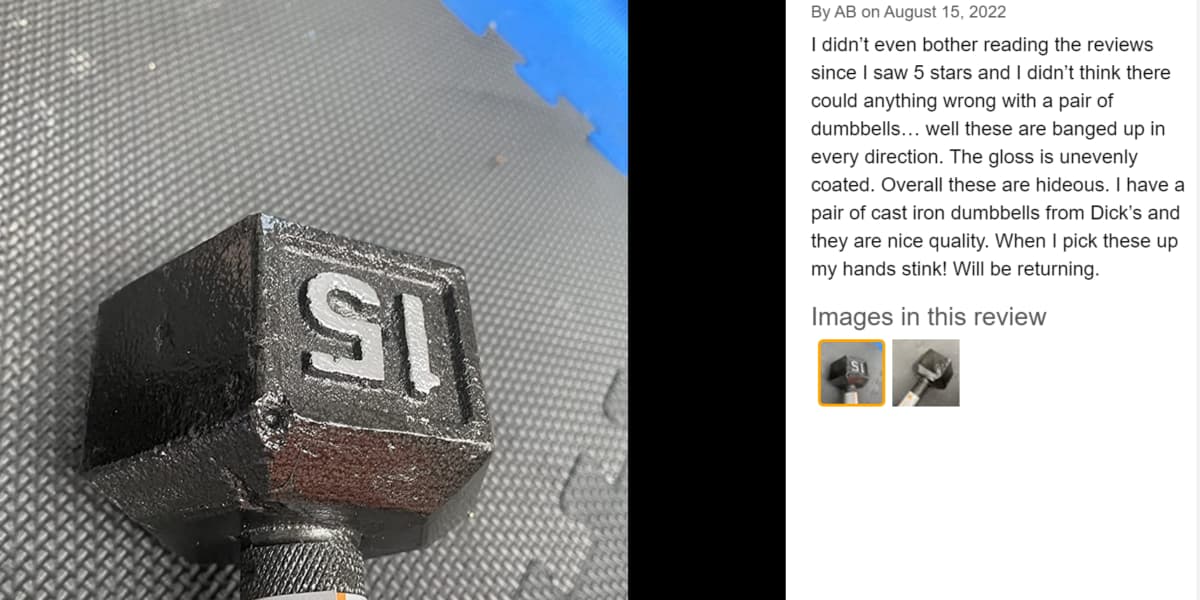

Surface problems of cast iron dumbbell ball heads produced by peers found on the Amazon website:

The surface performance of powder spraying is generally better, the main problem comes from the uneven grinding of the casting surface.

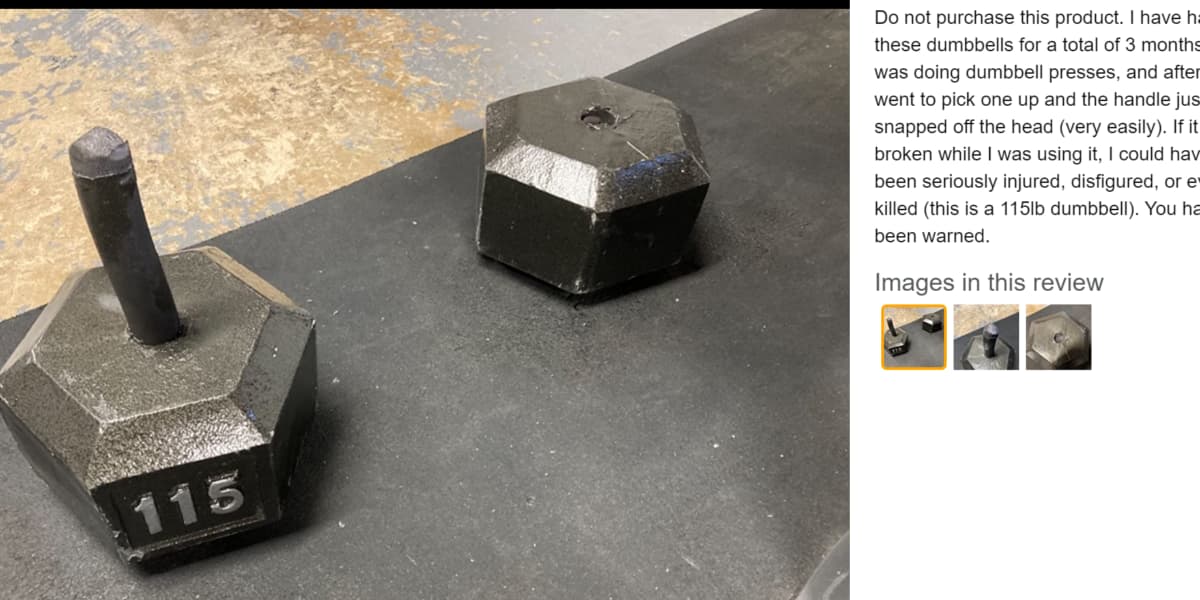

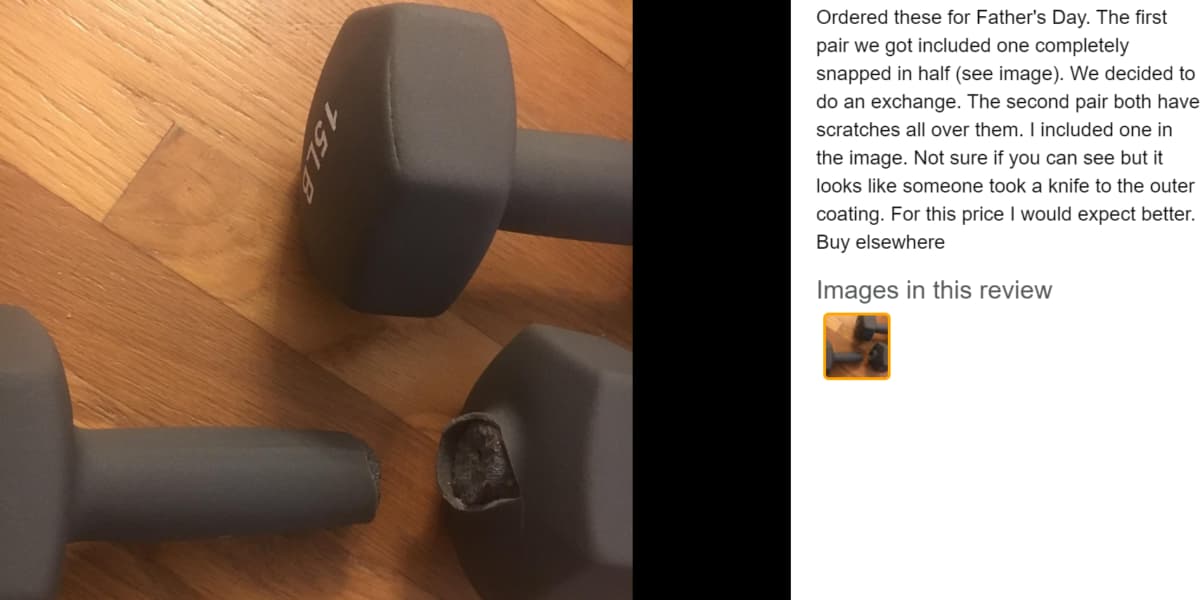

Here are cast iron dumbbell casting strength issues from peers found on Amazon:

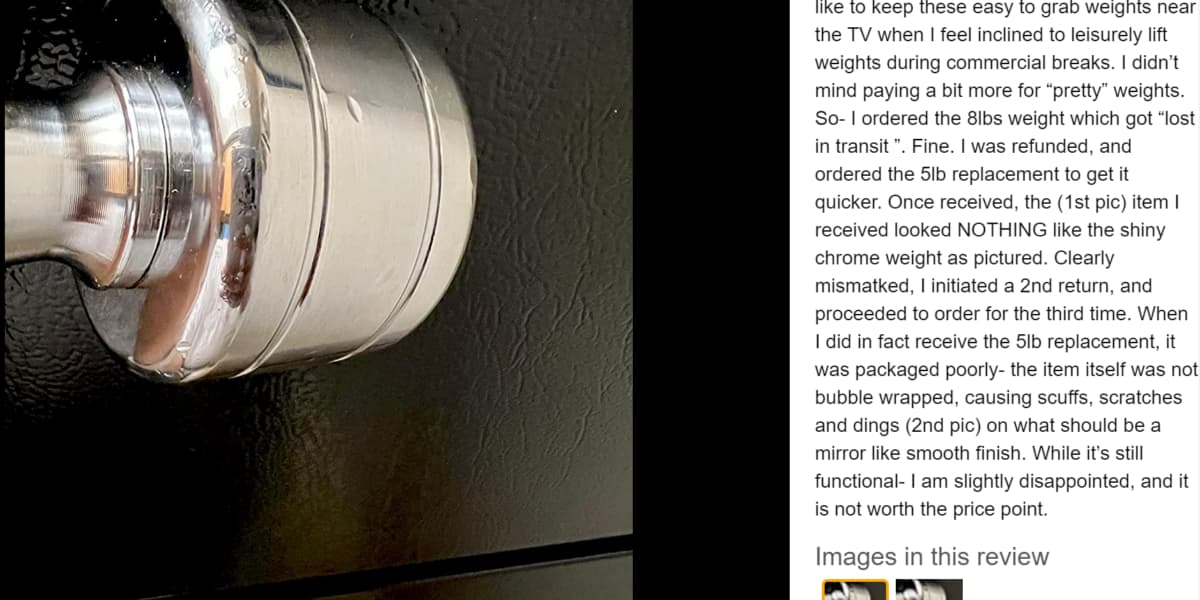

Since electroplating dumbbells are machined from round steel, their surface quality is likely to depend on the electroplating process. One is the level of electroplating, and the other is the thickness of electroplating. Generally speaking, the thicker the electroplating layer, the smoother the surface; electroplating If the level is poor and the surface is easy to peel, it will be very dangerous. The thin electroplated skin is like a knife. It is best to wear gloves when inspecting.

Since electroplating dumbbells are machined from round steel, their surface quality is likely to depend on the electroplating process. One is the level of electroplating, and the other is the thickness of electroplating. Generally speaking, the thicker the electroplating layer, the smoother the surface; electroplating If the level is poor and the surface is easy to peel, it will be very dangerous. The thin electroplated skin is like a knife. It is best to wear gloves when inspecting.

Bending problem of the electroplated dumbbell handle produced by the same industry found on the Amazon website:

Bending problem of the electroplated dumbbell handle produced by the same industry found on the Amazon website:

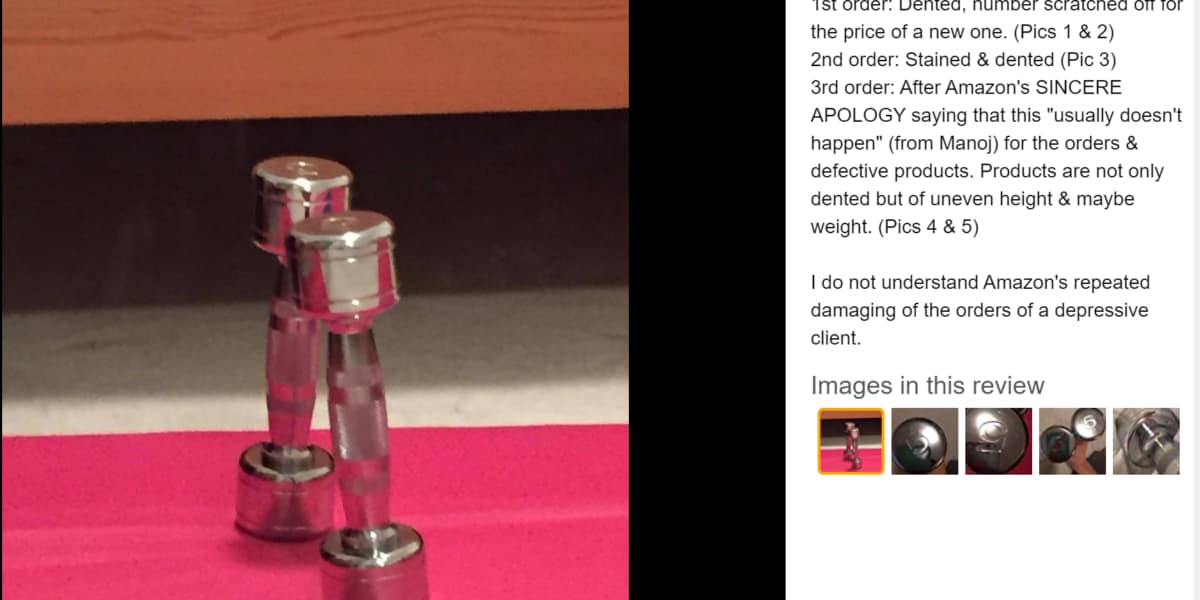

The following are the surface problems of electroplated dumbbells produced by peers found on the Amazon website:

The following are the surface problems of electroplated dumbbells produced by peers found on the Amazon website:

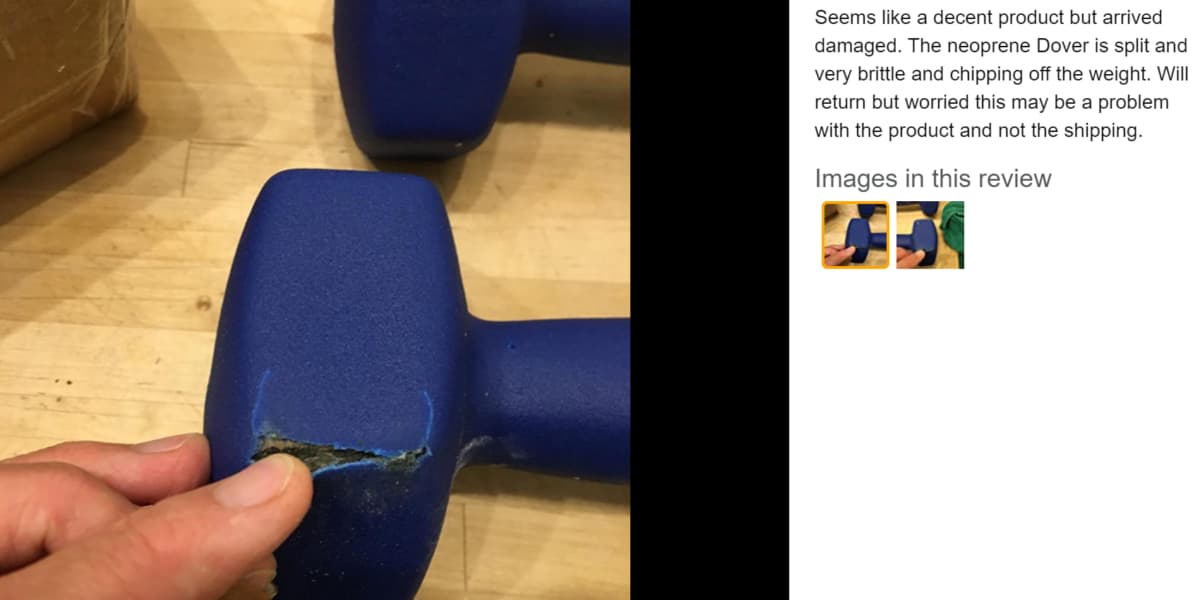

The surface of the rubber-covered dumbbell mainly checks several aspects

-

1. Whether the parting line is misaligned

-

2. Flashing

-

3. Blistering

-

4. The thickness of the rubber layer

-

5. The tensile value of the rubber (refer to the video)

-

6. Cracks (the mixing temperature is not Uniform)

-

7. Uneven

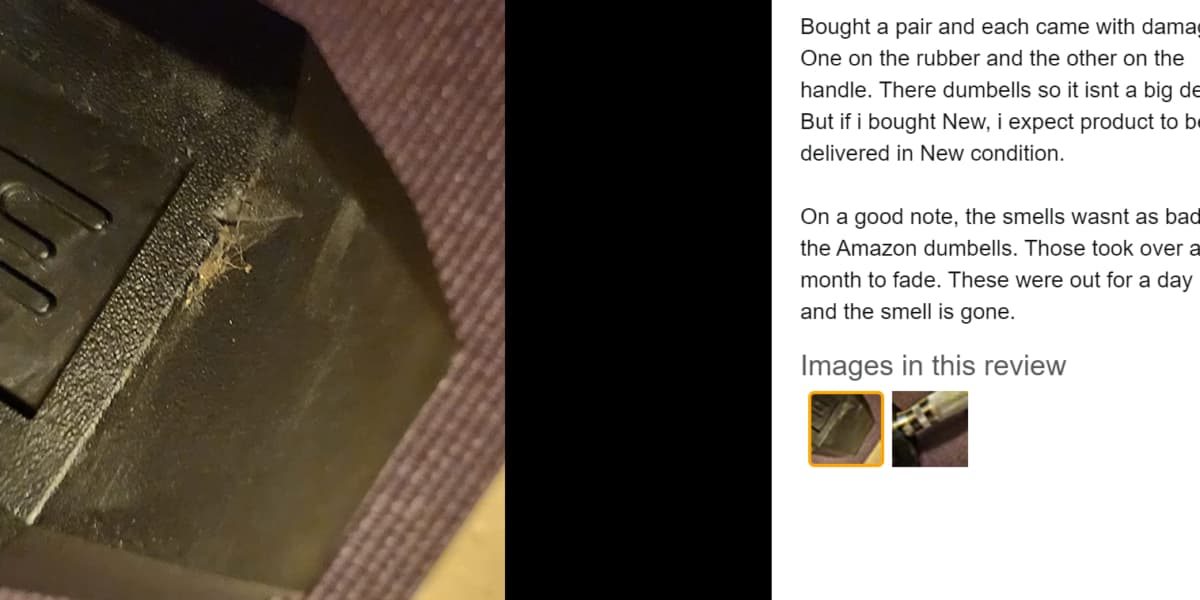

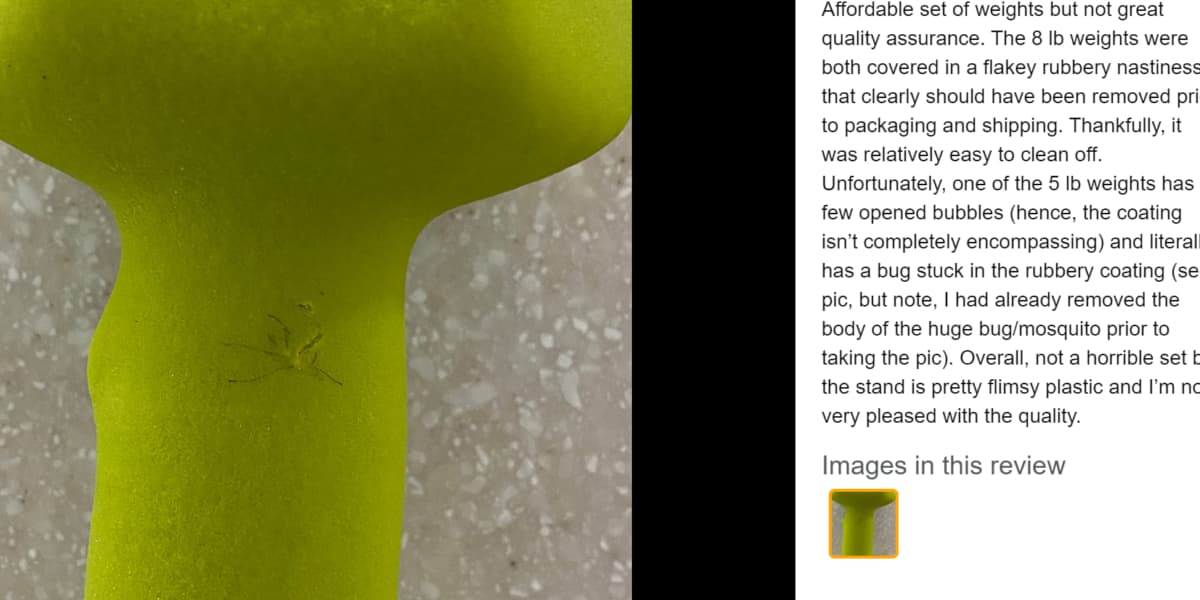

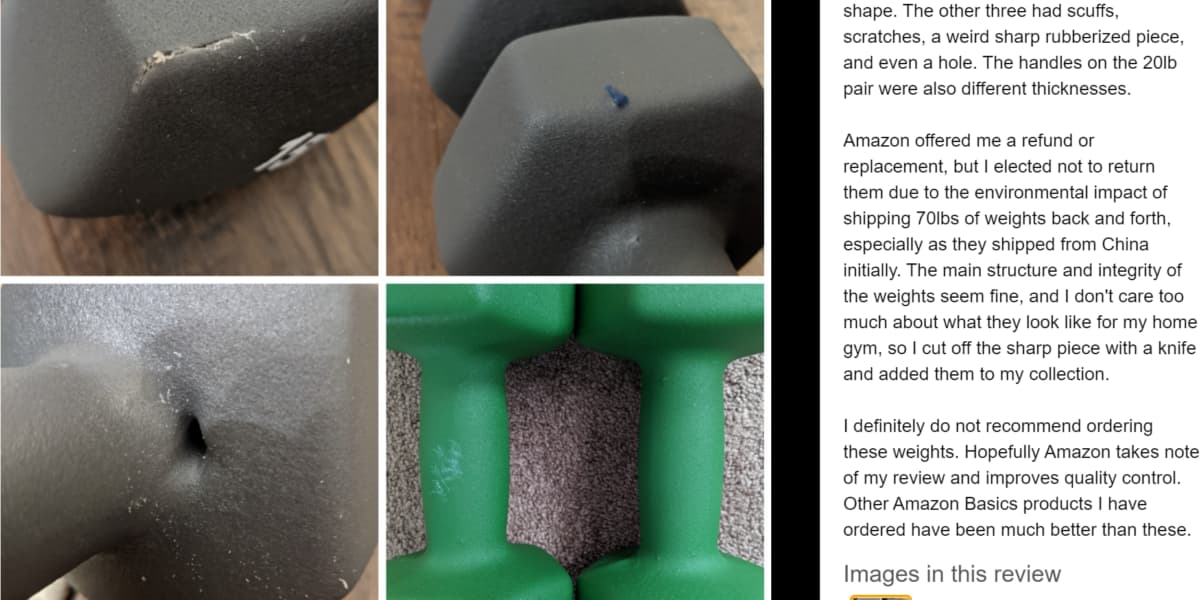

The following are the surface problems of rubber-coated dumbbells produced by peers found on the Amazon website (due to the large amount of rubber-coated dumbbells, there are various surface problems, and we found many screenshots):

The surface of the dipped dumbbell, note that due to the limitation of the production process, we hang the casting with a thin iron wire and immerse it in the dipping liquid. After cooling, we pull out the thin iron wire, so each dipped dumbbell will have a 4 small holes, this is unavoidable, the main problem of dipping dumbbells comes from the uneven grinding of the casting surface

Following are the surface problems of dipped dumbbells produced by peers found on the Amazon website:

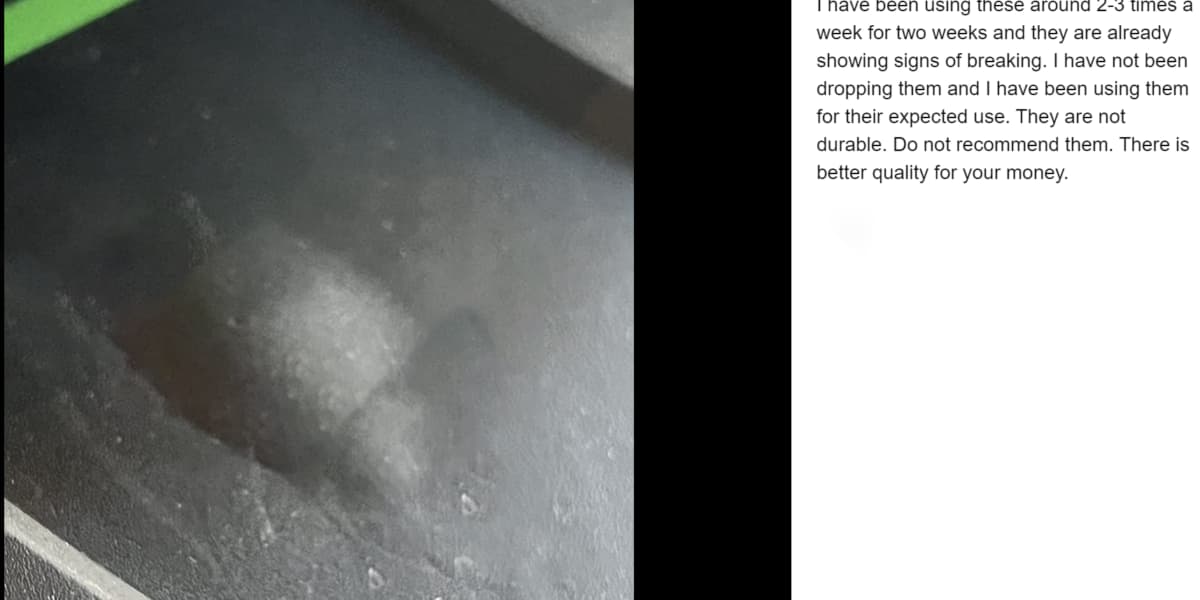

Following are the surface problems of dipped dumbbells produced by peers found on the Amazon website:

Because TPU is a blow molding process, the degree of automation is high. Generally speaking, there will be no problems on the surface. Of course, since PU dumbbells are used more frequently for commercial use, you can also do a tensile test if you think it is necessary (refer to below video ), or a drop test.

Because TPU is a blow molding process, the degree of automation is high. Generally speaking, there will be no problems on the surface. Of course, since PU dumbbells are used more frequently for commercial use, you can also do a tensile test if you think it is necessary (refer to below video ), or a drop test.

Compared with CPU and TPU, the surface quality is similar. Generally, brand dumbbells are customized for gyms. When inspecting the goods, pay attention to whether the LOGO of the glue filling part has any flashes. The accuracy should be very high.

It usually depends on whether the supplier has good control over the raw materials used. You can test the surface hardness of different products of the same batch, or the hardness of different batches of the same product, to see if their hardness is roughly the same (the detection method can refer to below video).

B. Handle

The surface of the handle, diameter

Generally, we should pay attention to several points on the surface of the handle:

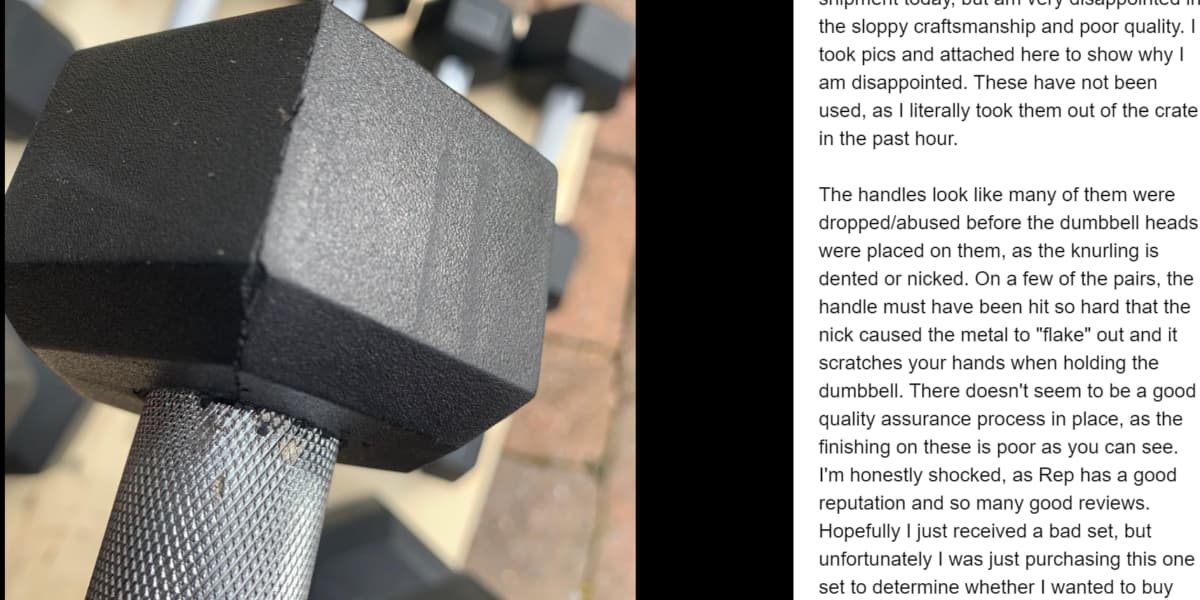

1. Flatness (whether there are bumps or pits on the surface by visual inspection or by hand)

1. Flatness (whether there are bumps or pits on the surface by visual inspection or by hand)

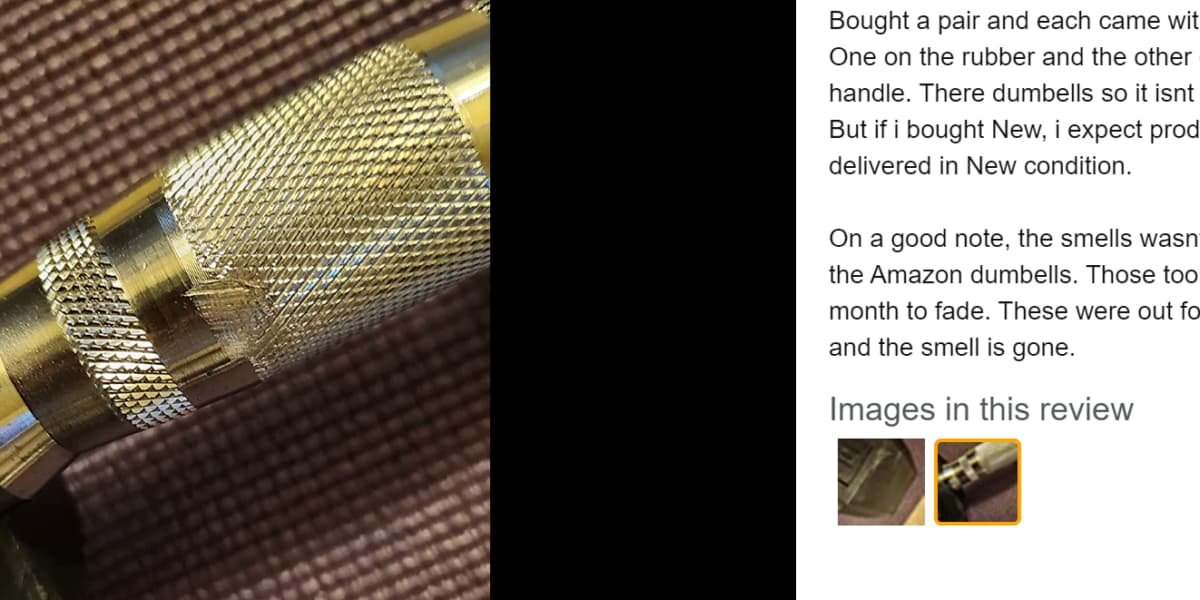

2. Flashing, usually a raised plating layer, is hard and sharp, very dangerous and must be completely avoided

3. Whether the electroplating is uniform, see if there is any color difference on the electroplating surface

*The handles of cast iron dumbbells or plastic-impregnated dumbbells are slightly different from the above situation. They all have ball heads and handles integrated, so focus on checking the surface quality, size and weight, and you can also do a drop test.

The following is a problem with the rubber-covered dumbbell handle of the same manufacturer found on the Amazon website:

C. Weight Normally tolerance is ±3%, unless otherwise specified

C. Weight Normally tolerance is ±3%, unless otherwise specified

The following are the weight problems of rubber-covered dumbbells produced by peers found on the Amazon website:

D. Tensile test of rubber/PU (please refer to the video)

E. Knurling

There are three types of knurling (refer to the classification of Olympic bar knurling), please check carefully whether it is consistent with the type of knurling you require from the supplier; when checking the knurling of the handle, focus on the clarity.

Here are the dumbbell knurling issues from peers found on Amazon:

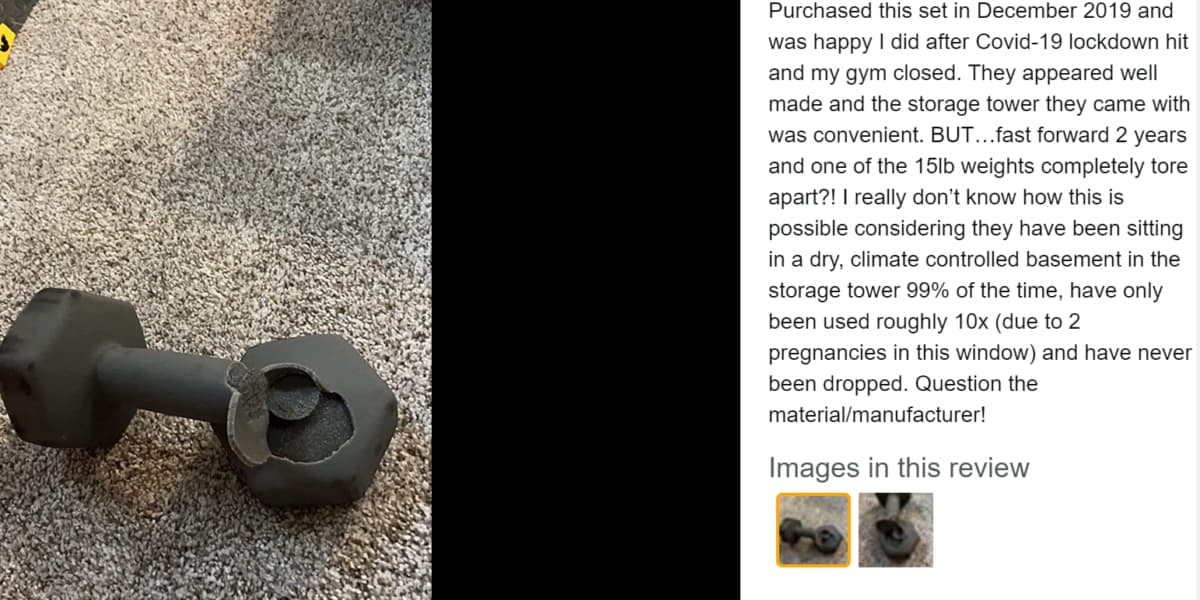

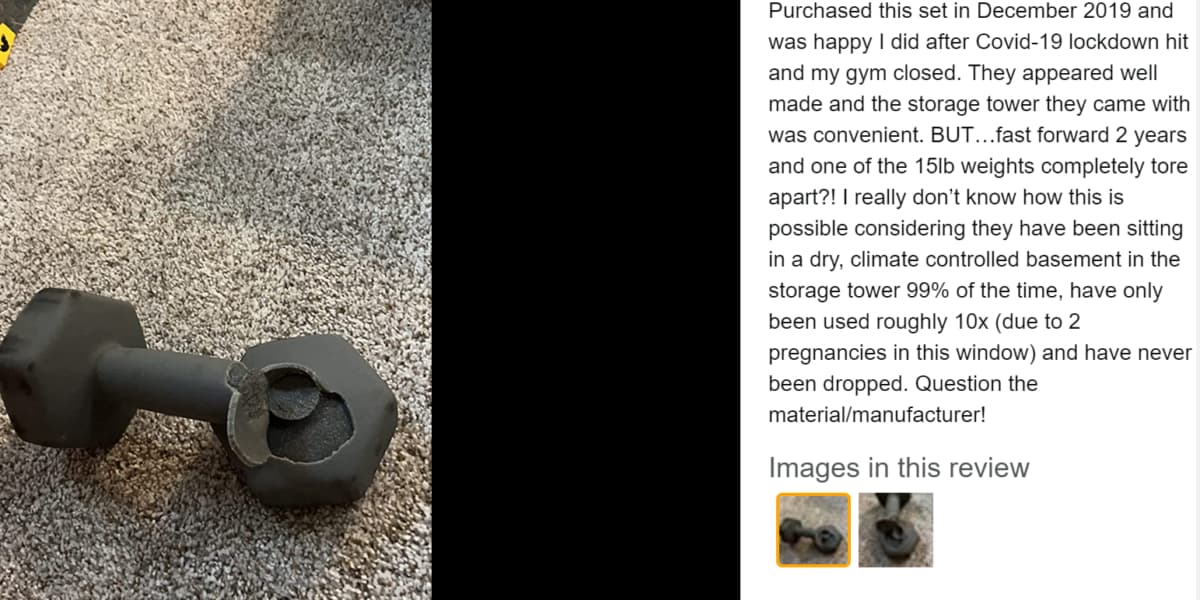

F. Drop test

F. Drop test

Usually we simulate the height used by the user in the gym and repeatedly throw it on the rubber mat to see its wear and tear. Of course, we can also increase the height according to the demand for limit testing.

The following are the strength problems of dipped dumbbells produced by peers found on the Amazon website:

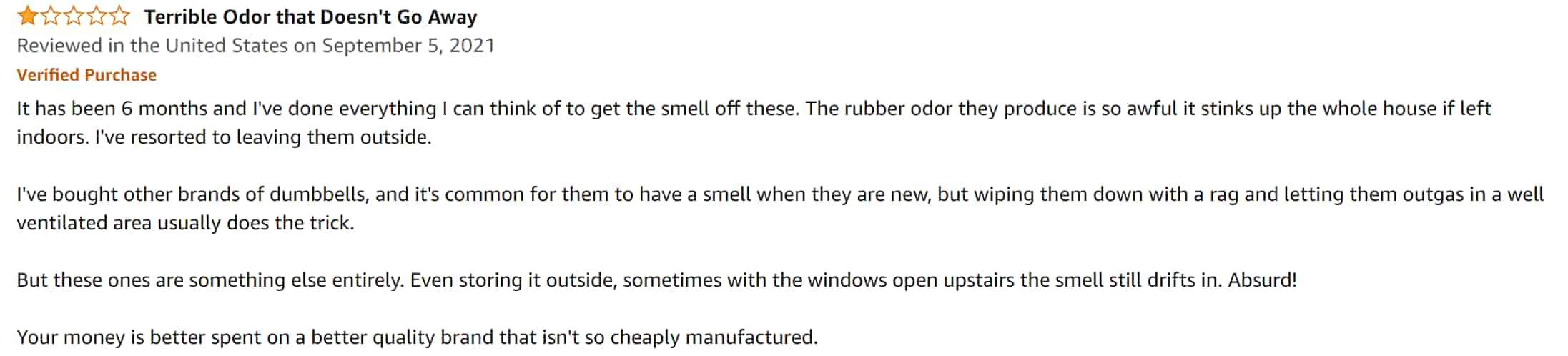

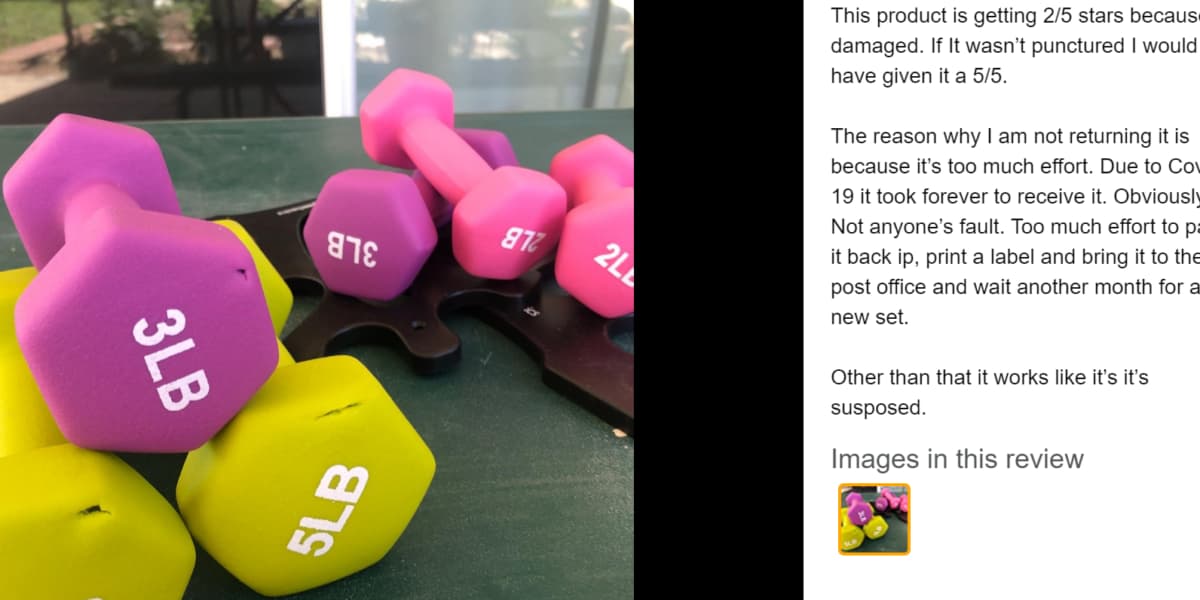

G. smell

The following are the odor problems of dumbbells produced by peers found on the Amazon website:

3. Tips for Checking Weight Plats

Weight plates can be divided into cast iron, pure steel competitive, rubber-covered, full rubber and PU weight plates according to the material.

A. Cast iron weight plates

Look at the surface (attached paint or powder), shape, size, weight (tolerance), drop test.

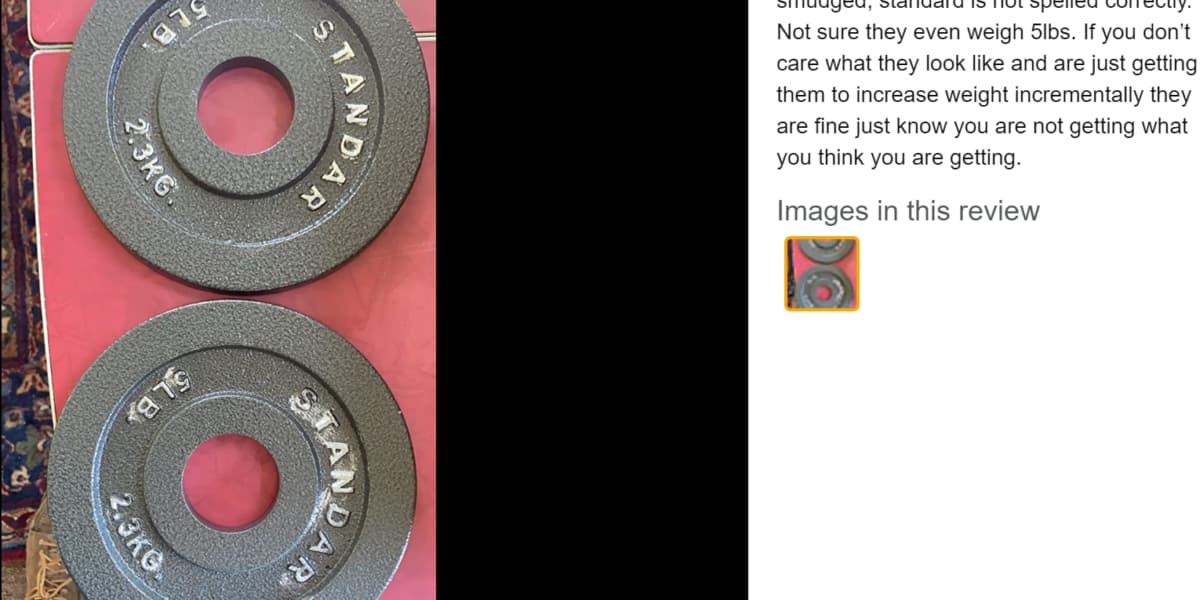

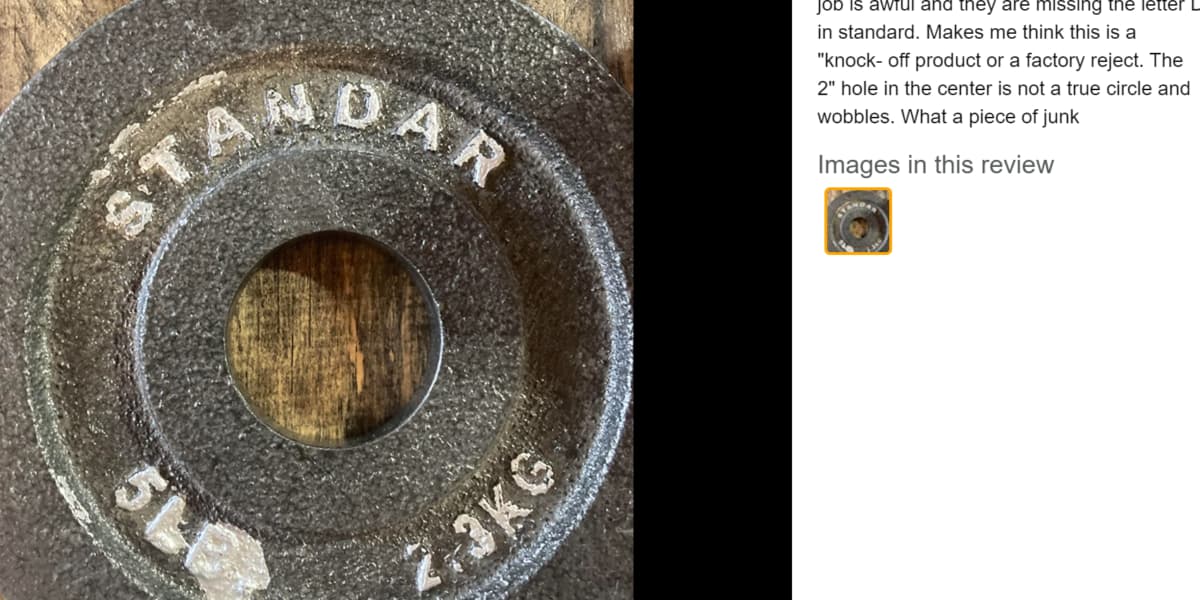

The following are the surface problems of cast iron plates produced by peers found on the Amazon website:

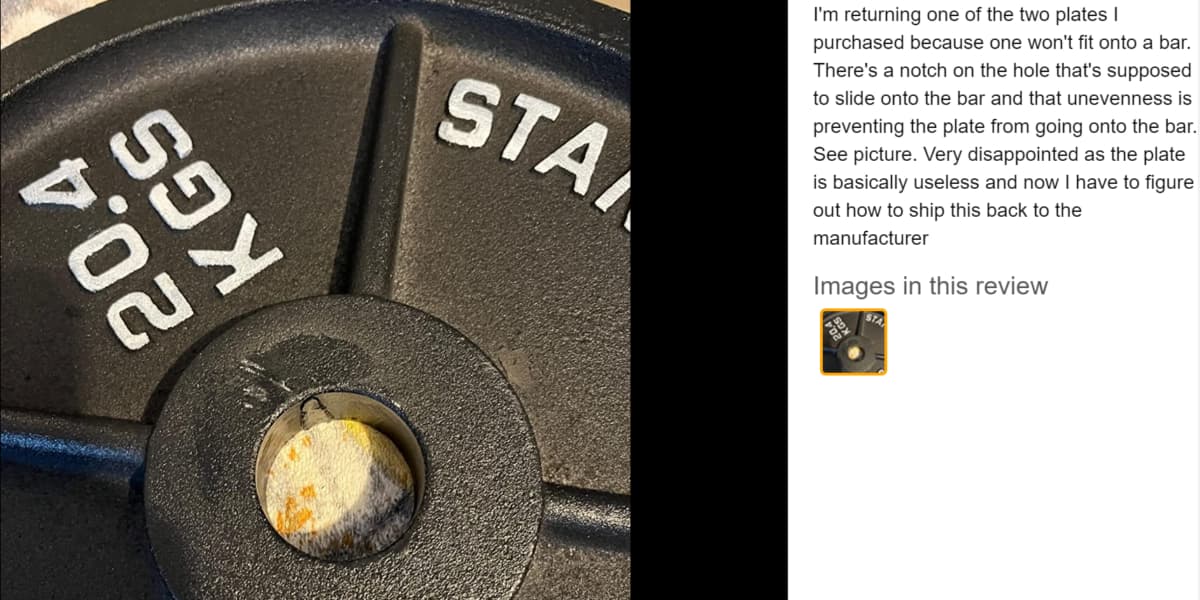

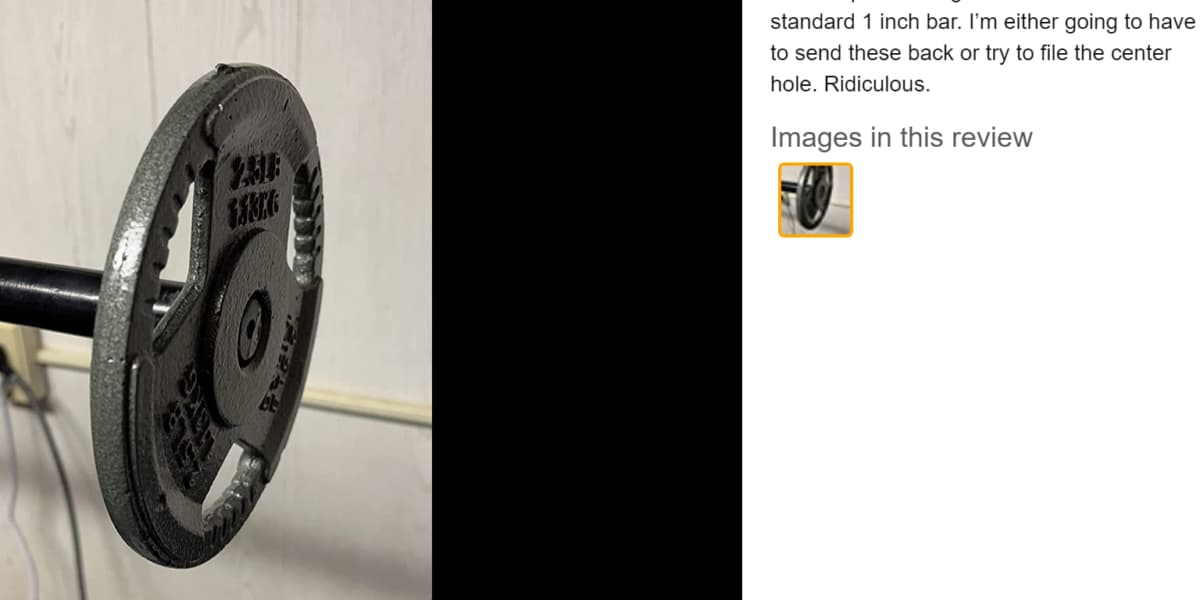

The following is the hole diameter problem of the cast iron plate produced by the same industry found on the Amazon website:

The following is the hole diameter problem of the cast iron plate produced by the same industry found on the Amazon website:

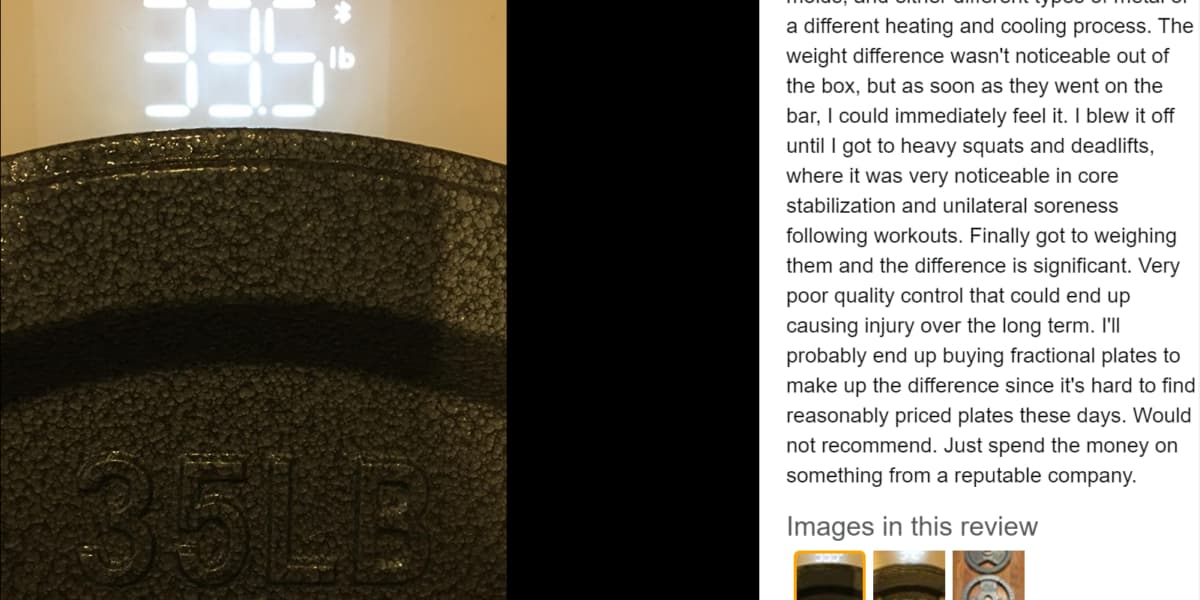

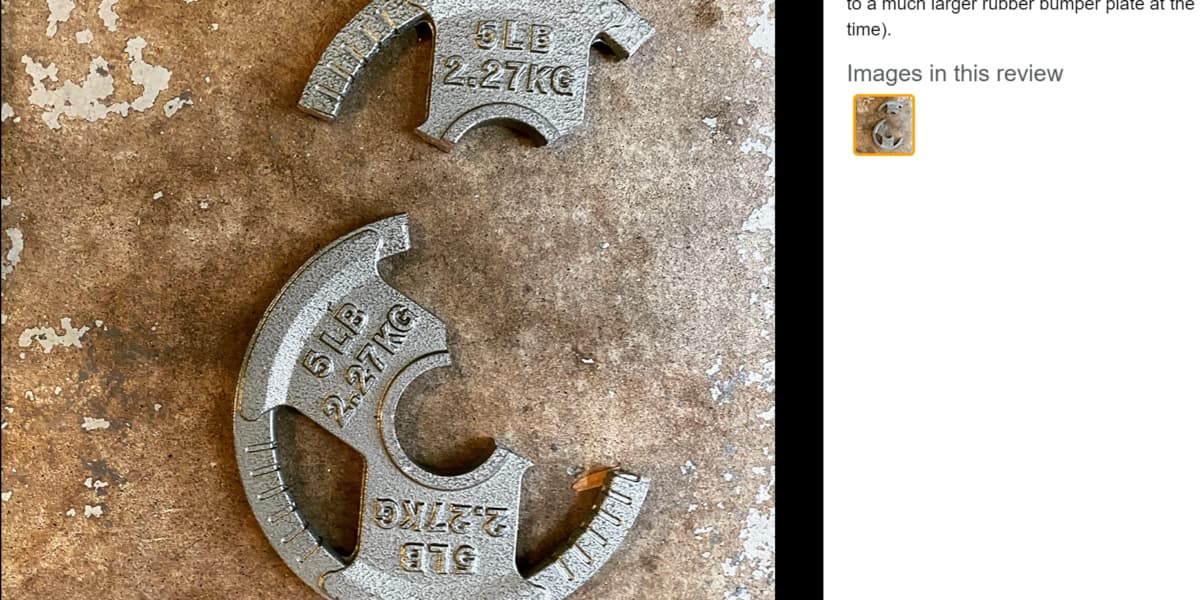

Following is the weight problem of cast iron plates produced by peers found on the Amazon website:

Following is the weight problem of cast iron plates produced by peers found on the Amazon website:

The details of the paint can refer to the attention points of the surface paint inspection of the dumbbell.

The details of the paint can refer to the attention points of the surface paint inspection of the dumbbell.

Pay special attention to the hole diameter, generally, not less than 50.4MM, because the diameter of the sleeve of the Olympic bar is 50MM.

The weight tolerance is ±3%, and the drop test can refer to the test method of dumbbells.

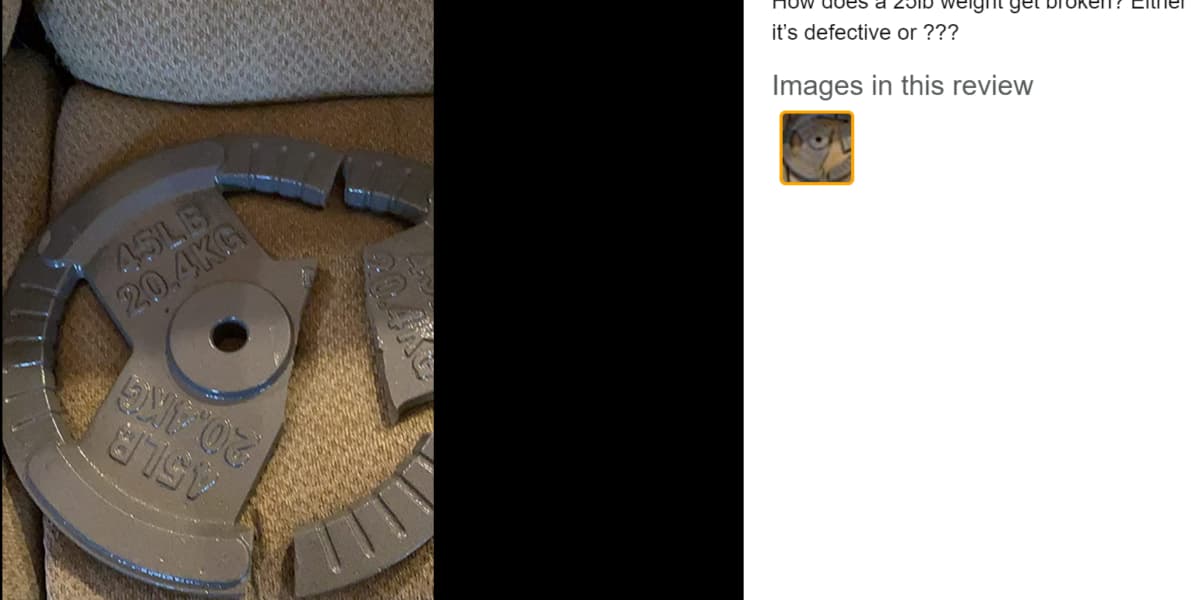

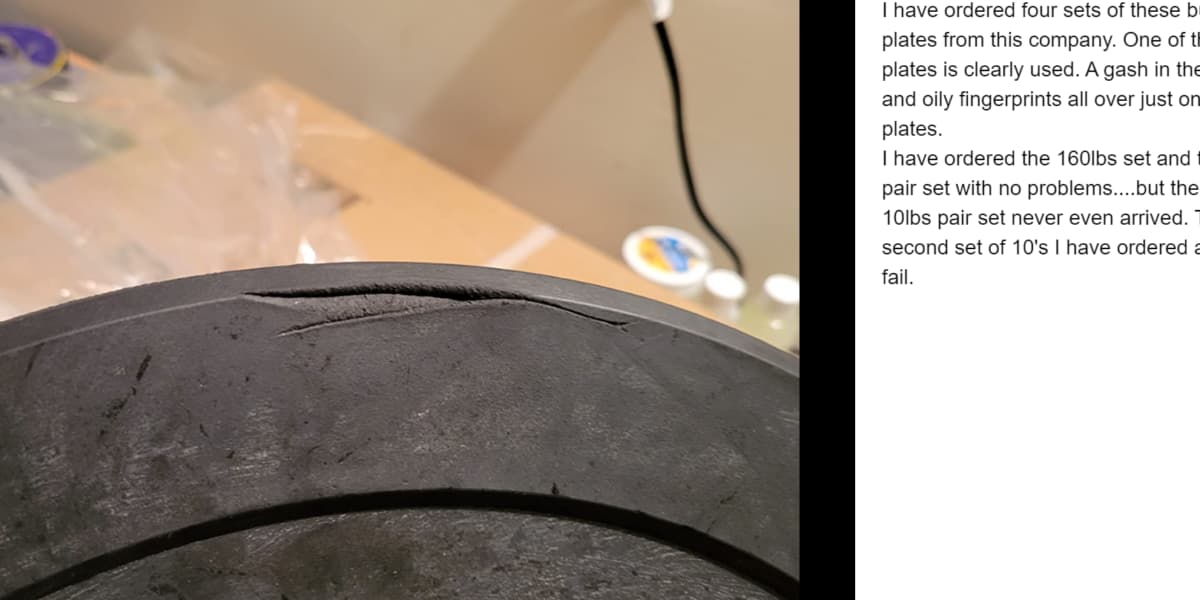

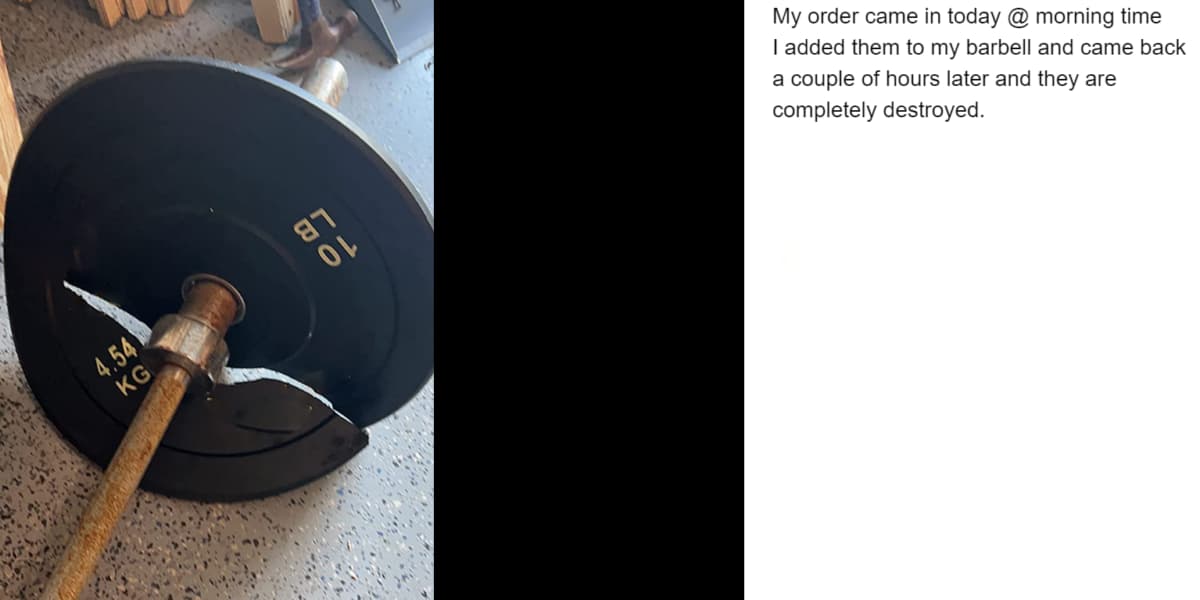

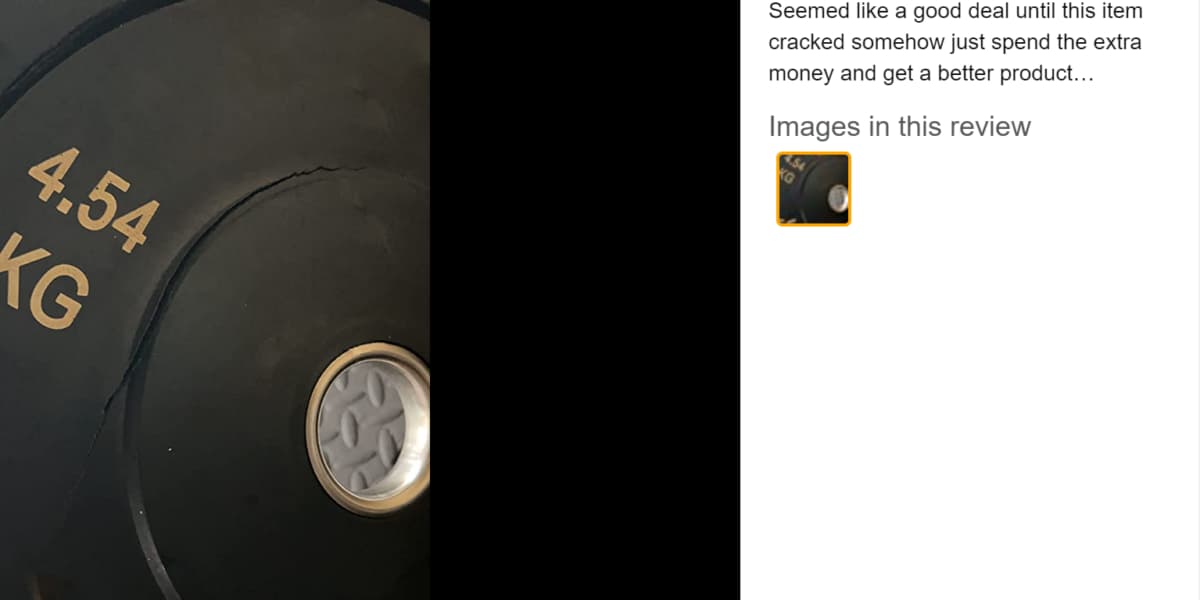

The following are the strength issues of cast iron plates produced by peers found on the Amazon website:

B. Pure steel competitive film

B. Pure steel competitive film

Look at the surface, size, weight, drop test, font LOGO

At present, most of the pure steel sports chips are powder-sprayed. Because the rings will be shot blasted before powder spraying, the surface will have a grainy texture. Please pay attention to check whether there are large bumps or flashes on the surface.

The outer size is 45CM, and the aperture is generally not less than 50.4MM

The weight tolerance is ±3%, and the drop test can refer to the test method of dumbbells.

LOGO can be silk screen printing or laser, the color fastness of silk screen printing is a bit poor, but the laser effect will be more stable, you can use a rag to wipe it hard to see the color fastness.

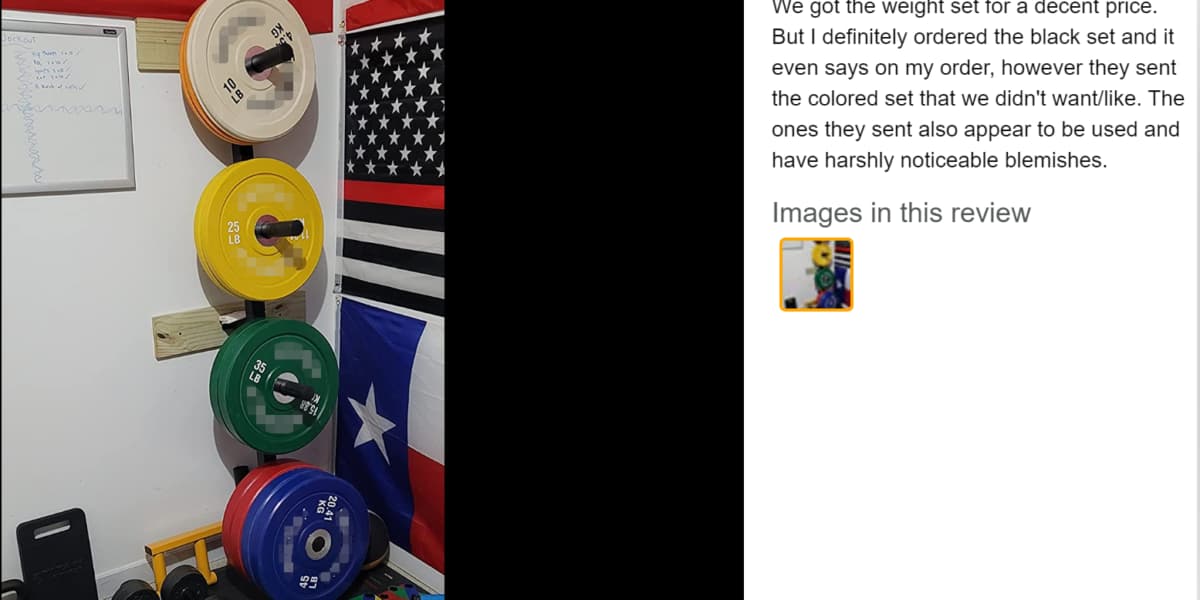

C. Rubber coated weight plates

Look at the surface, shape, size, weight, drop test, smell, stickers (if any), hardness.

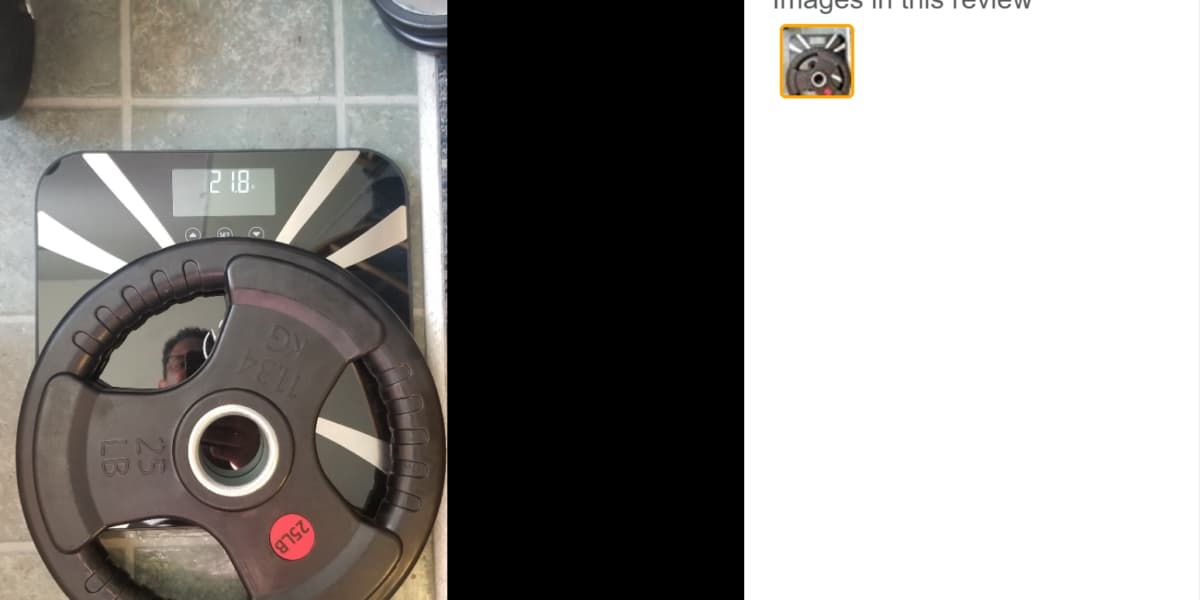

The following is the weight of the rubber-covered weight plates produced by the same industry found on the Amazon website:

For surface inspection, you can refer to the surface inspection process of rubber-coated dumbbells.

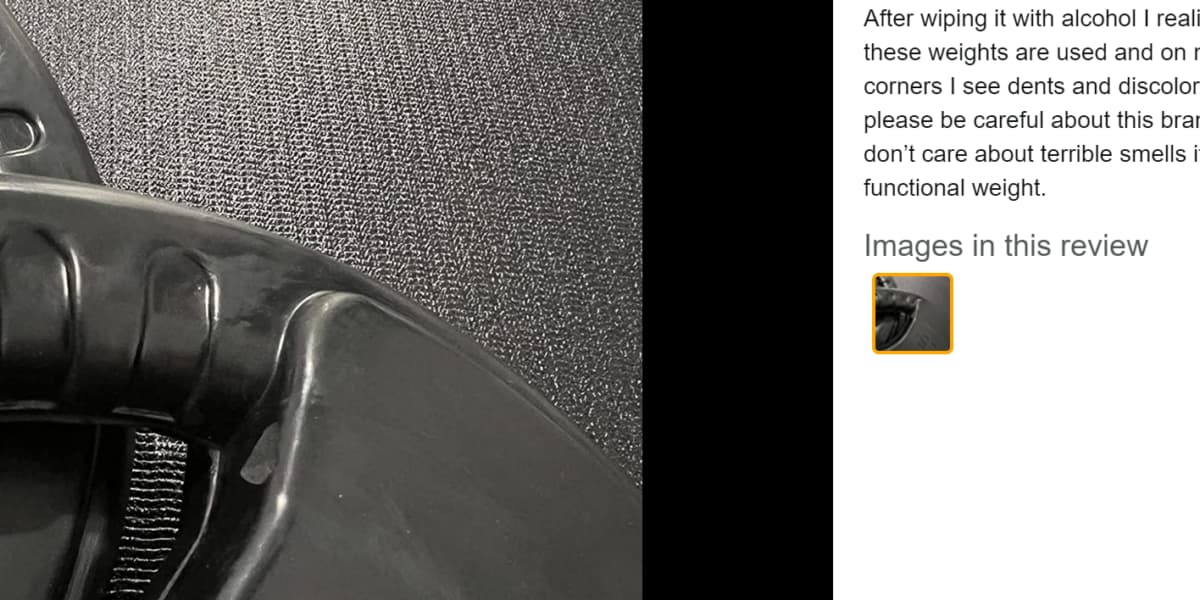

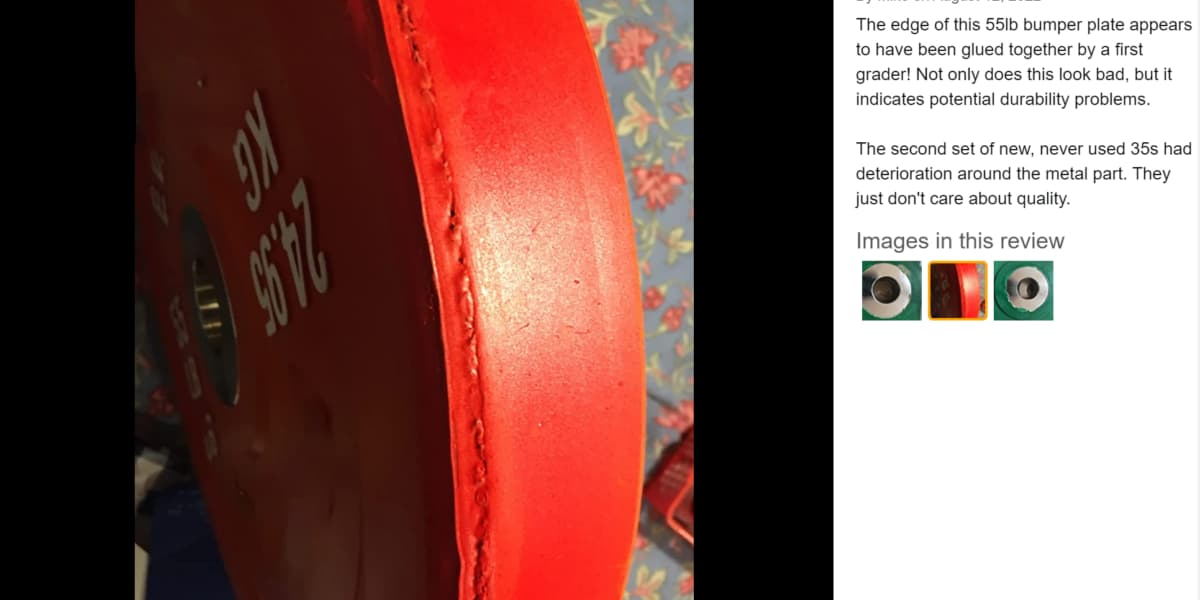

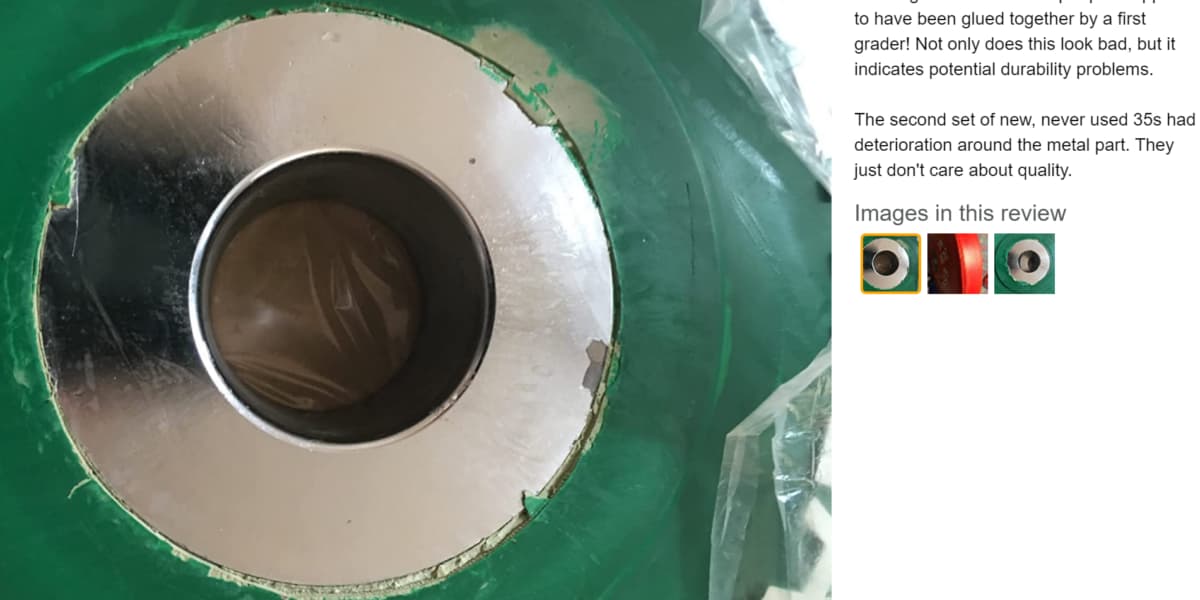

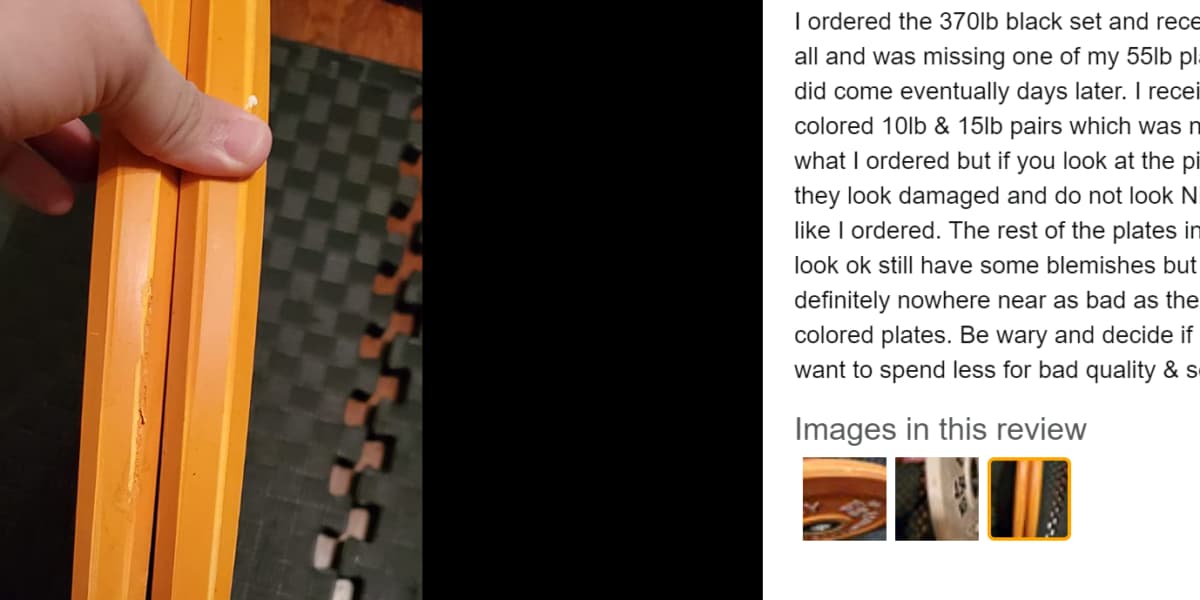

The following are the superficial problems of the rubber-covered weight plates produced by competitors found on the Amazon website:

The middle ring is made of electroplated iron and stainless steel, and the inner diameter is generally not less than 50.4mm.

Generally, the rubberized free weight products made in China are divided into ordinary rubber (recycled rubber remelted) and virgin rubber. The surface hardness of virgin rubber is low and almost odorless.

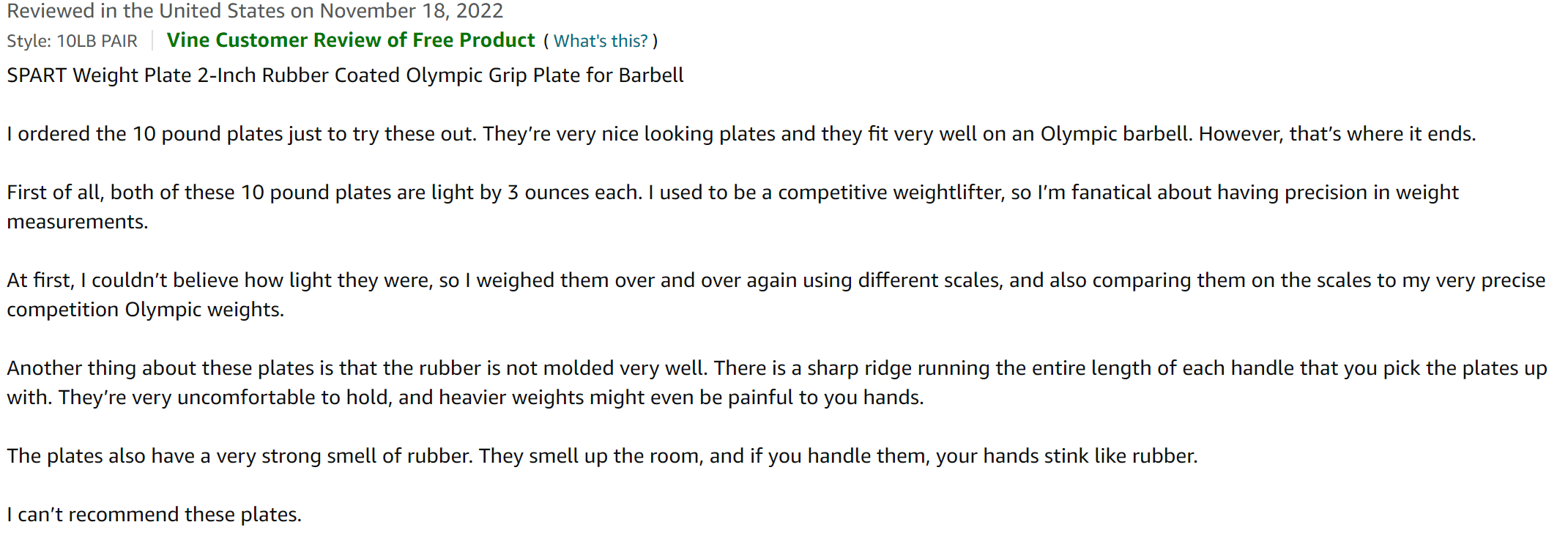

The following are the odor problems of the rubber-covered weight plates produced by the same industry found on the Amazon website:

Labels are generally made of PVC and PU. When checking, pay attention to the clarity of the font and whether there are oily stains that are difficult to remove.

D. Full rubber

Look at the surface, size weight, drop test, smell, stainless steel sleeve, font (embossed and printed) clarity, hub (if any), hardness, etc.

The following are the odor problems of the full rubber weight plates produced by the same industry found on the Amazon website:

If the heating is insufficient/uniform, or the rubber raw material is not sufficiently mixed, or the design of the mold vent hole is unreasonable, problems such as blisters and cracks will appear on the surface

If the heating is insufficient/uniform, or the rubber raw material is not sufficiently mixed, or the design of the mold vent hole is unreasonable, problems such as blisters and cracks will appear on the surface

Here are the superficial issues with the all-rubber jingles found on Amazon:

The outer diameter is generally standard 45 cm, and the inner diameter of the stainless steel sleeve is not less than 50.4 mm.

The outer diameter is generally standard 45 cm, and the inner diameter of the stainless steel sleeve is not less than 50.4 mm.

If it is a hub plate, check the surface treatment of the hub.

Since it is a full rubber, customers often prefer to test its resilience, which is different from ordinary drop tests. It is recommended to perform a drop test after being symmetrically placed on the Olympic bar to measure the degree of resilience.

The following is the strength of the full rubber plate produced by the peers found on the Amazon website:

The color is in accordance with the national standard color, the following is the color problem of the full rubber plates produced by the same industry found on the Amazon website:

The color is in accordance with the national standard color, the following is the color problem of the full rubber plates produced by the same industry found on the Amazon website:

E. PU weight plates

Look at the surface, size weight, drop test, smell, stainless steel sleeve, font (embossed and printed) clarity, hub (if any), hardness, etc.

Compared with lagging, the surface of PU is more uniform.

No smell, the drop test surface is more excellent, wear-resistant and drop-resistant, more used in commercial gyms, etc.

4. Tips for Checking Kettlebells

According to the material, kettlebells can be divided into: cast iron kettlebells, competition kettlebells, plastic-coated kettlebells, dipped kettlebells, PU kettlebells

A. Cast Iron Kettlebells

Look at the surface, size and weight, drop test, font (embossed and printed) clarity, handle (whether to paddle), bottom surface

The surface of the painted/painted and dusted kettlebell depends on the quality of the casting surface process, the fineness of grinding, and the level of machining treatment on the one hand.

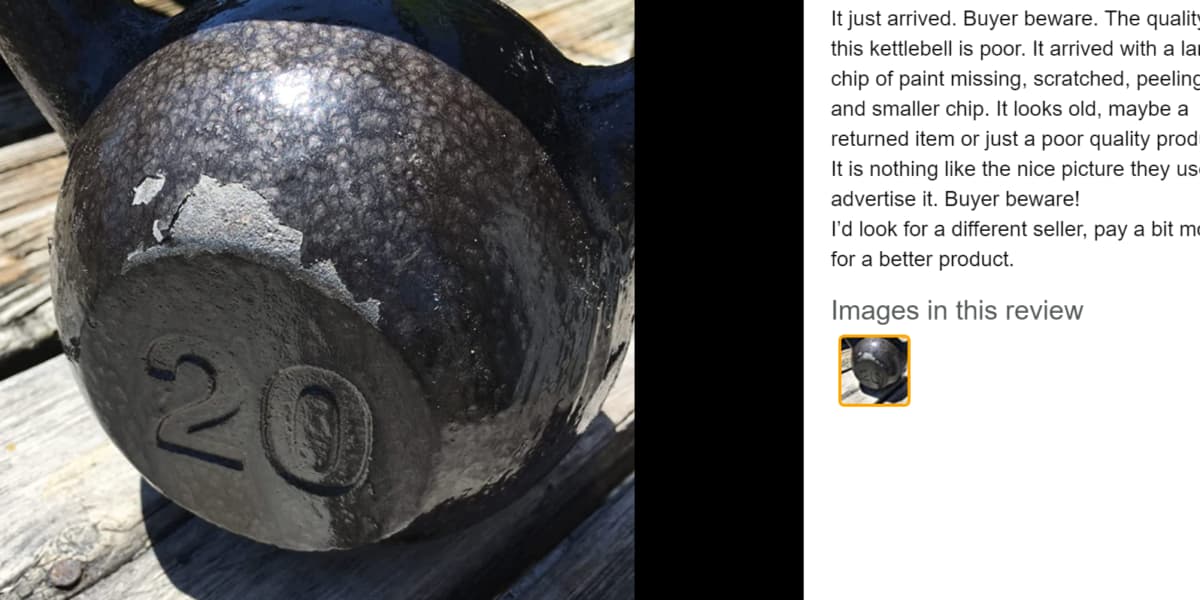

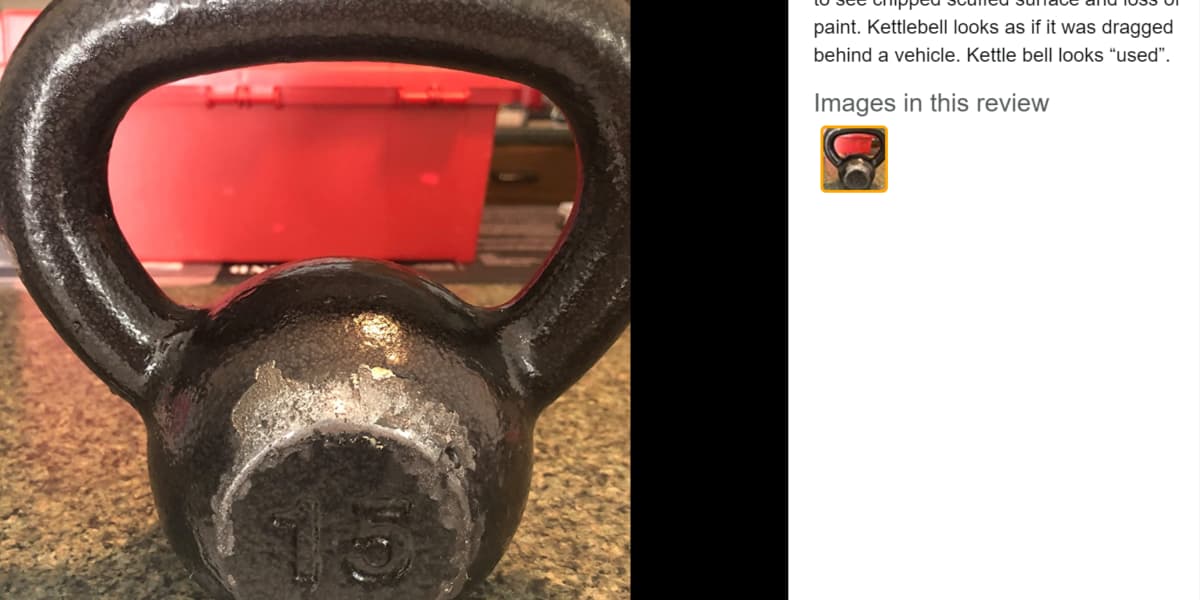

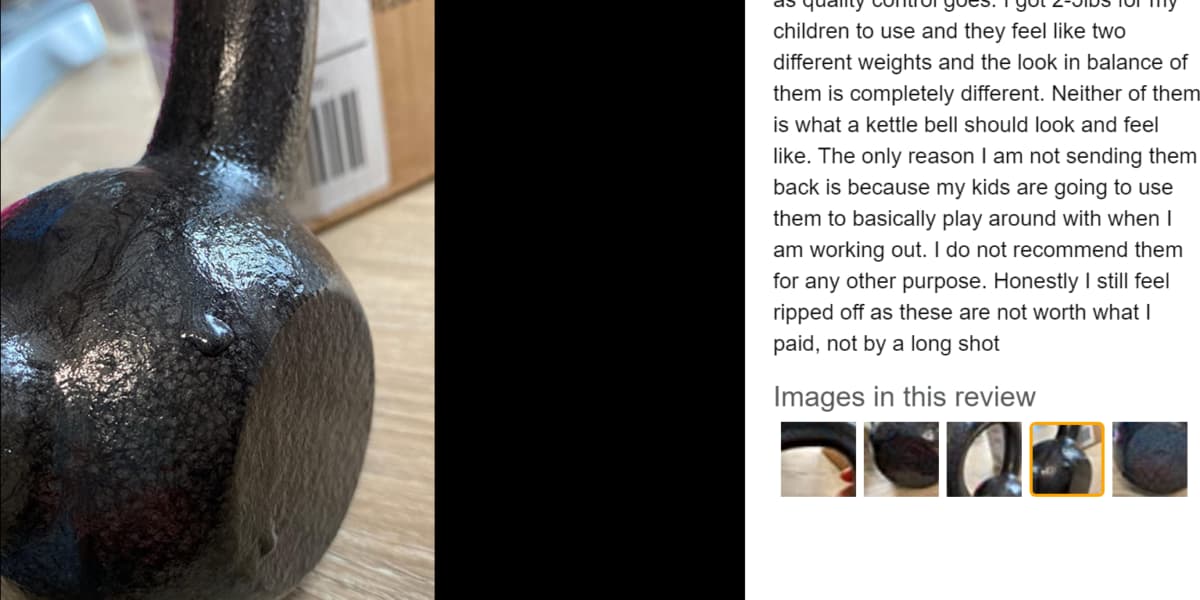

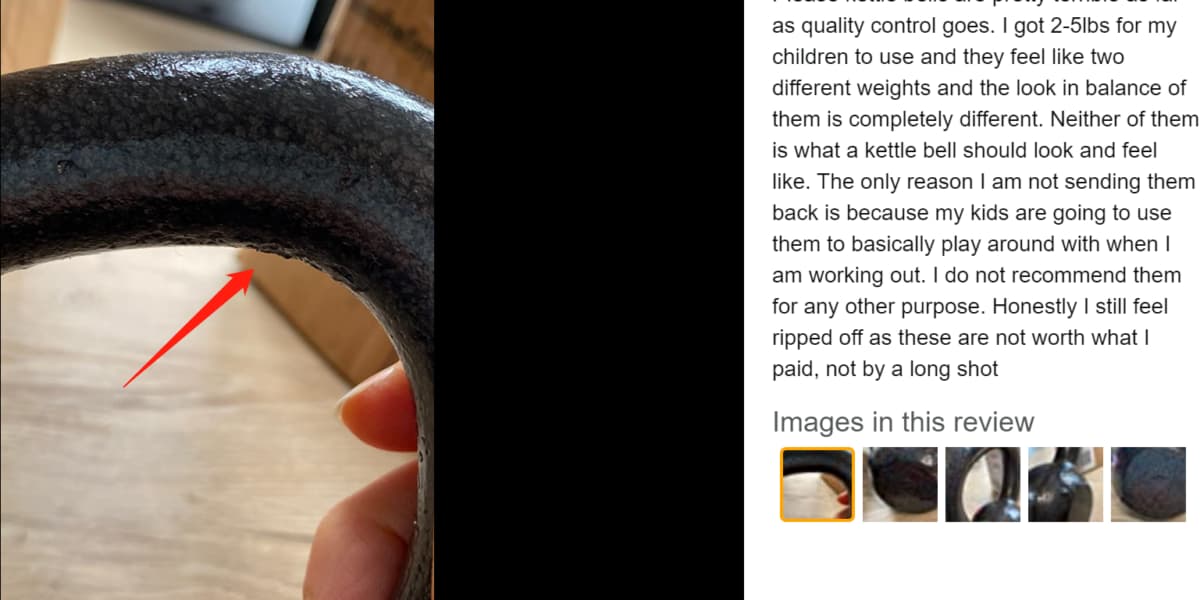

Here are the superficial issues with cast iron kettlebells from peers found on Amazon:

Pay attention to the phenomenon of hanging paint:

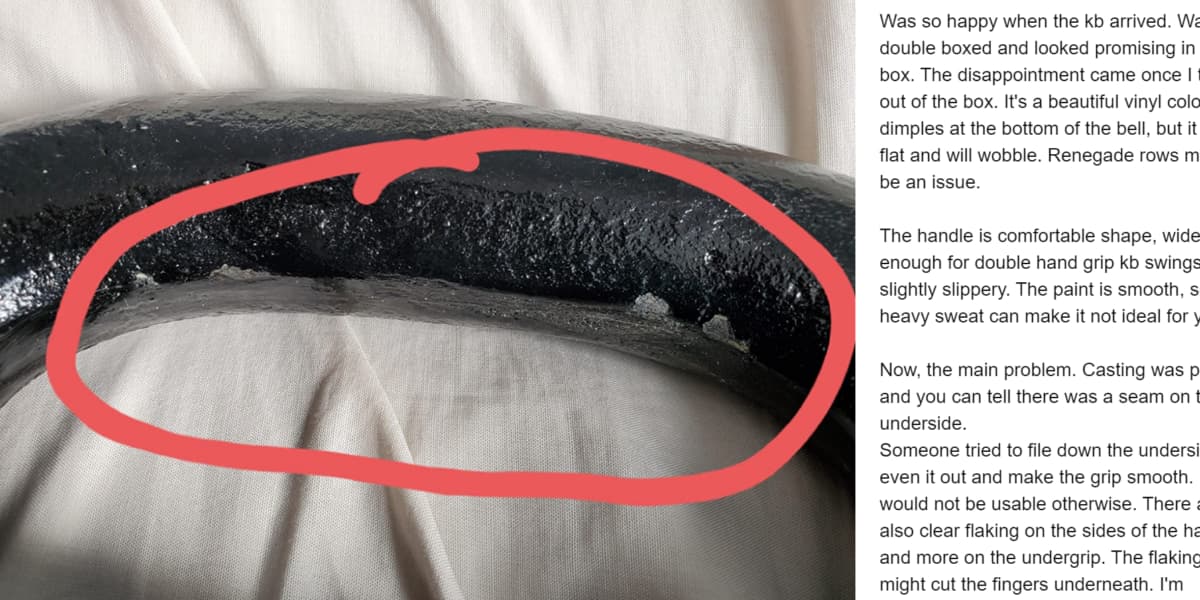

The diameter of the handle can be measured with a vernier caliper, carefully check the smoothness of the handle

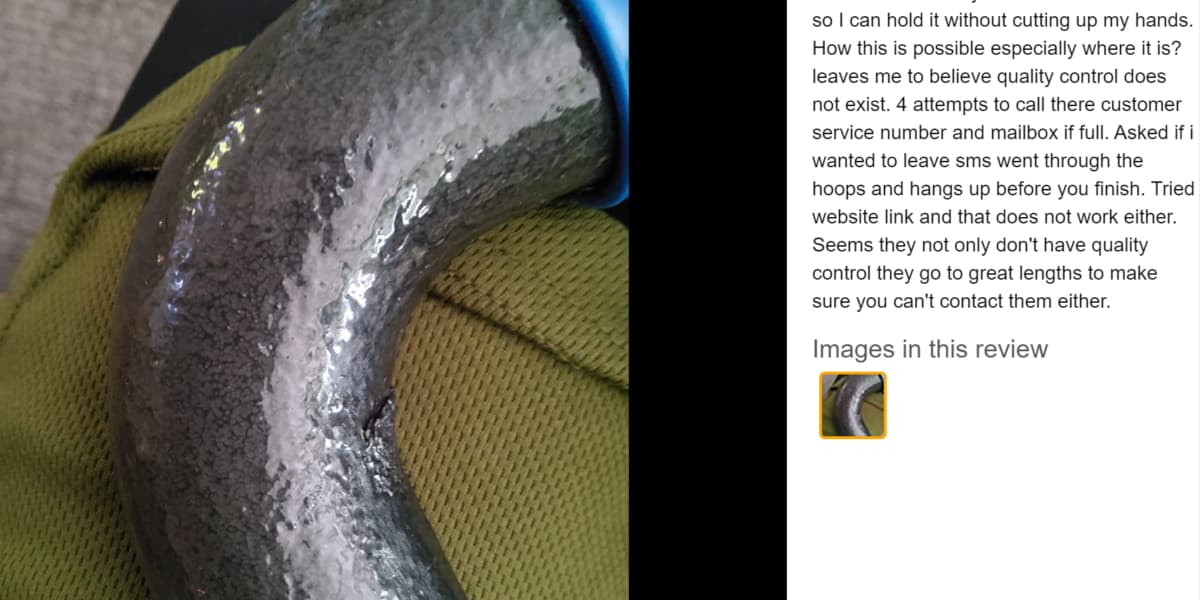

Here’s the handle issue with a competitor’s cast iron kettlebell found on Amazon:

The clarity of the font depends on the precision of the mold and the casting process (ranking by effect: lost foam > coated sand > mechanical casting > manual sand casting), and of course the casting cost of coated sand is also high

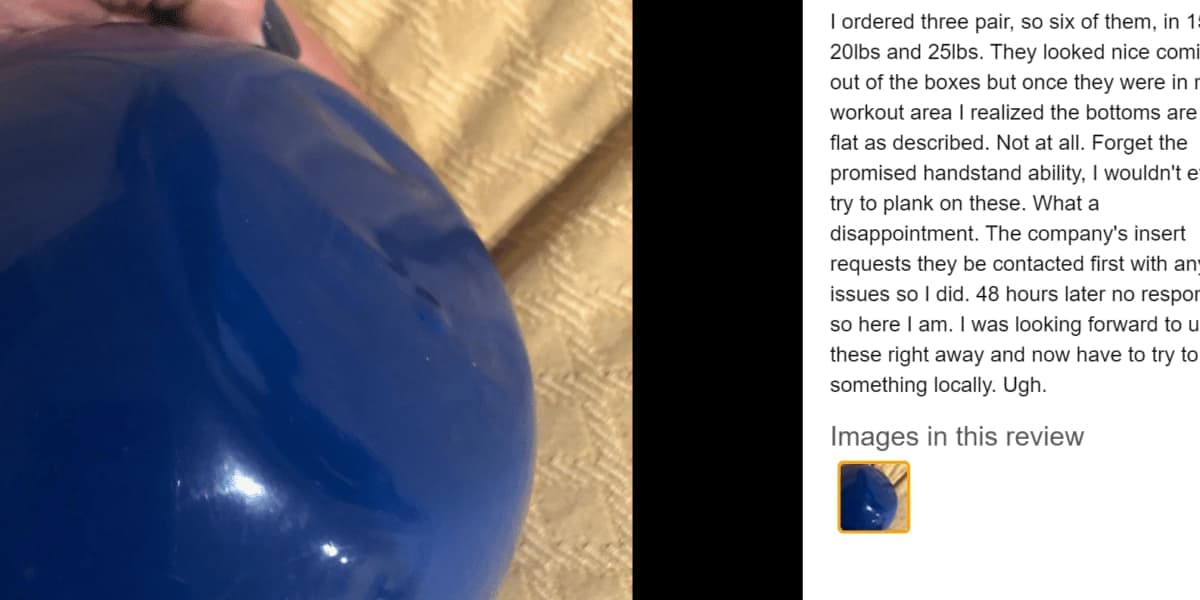

Look at the flatness of the bottom surface, how is the machining level?

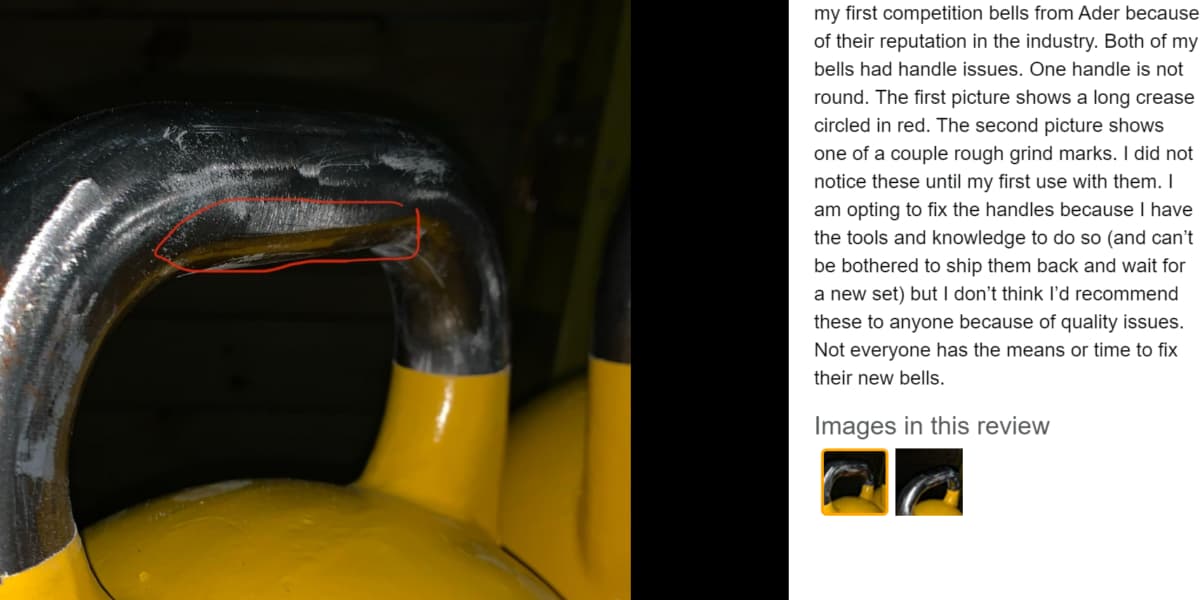

B. Competition Kettlebells

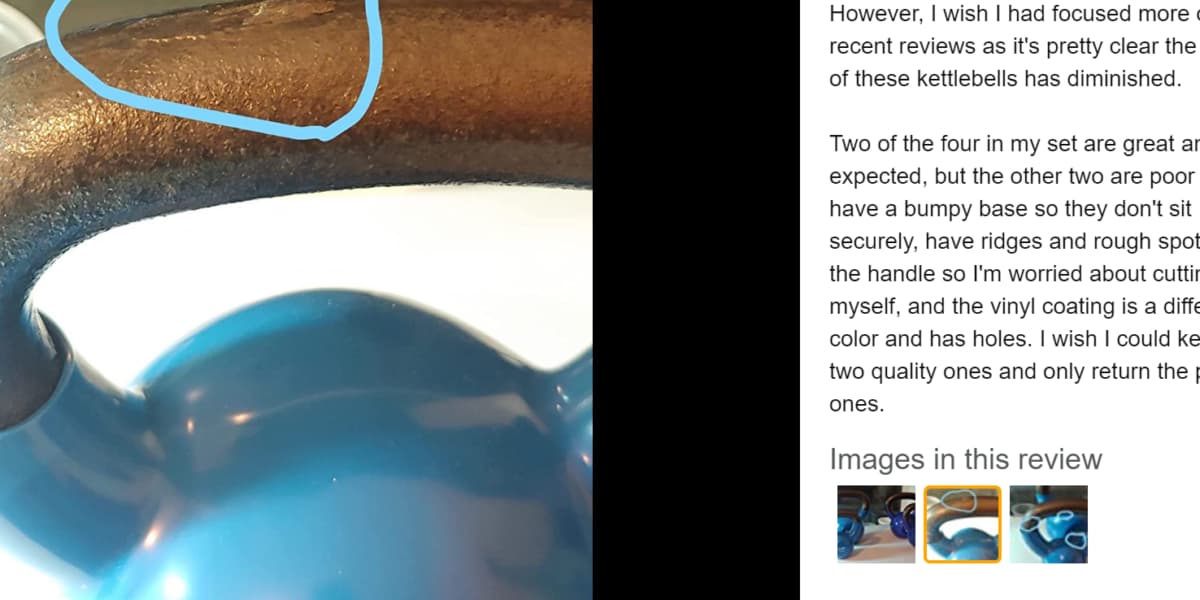

Look at the surface, size and weight, drop test, font (concave-convex and printed) clarity, handle welding, bottom surface, whether there is sound when the pot shakes, and whether the center of gravity of the pot is in the center.

There are almost no problems with the surface of the competition kettlebell, but there are exceptions:

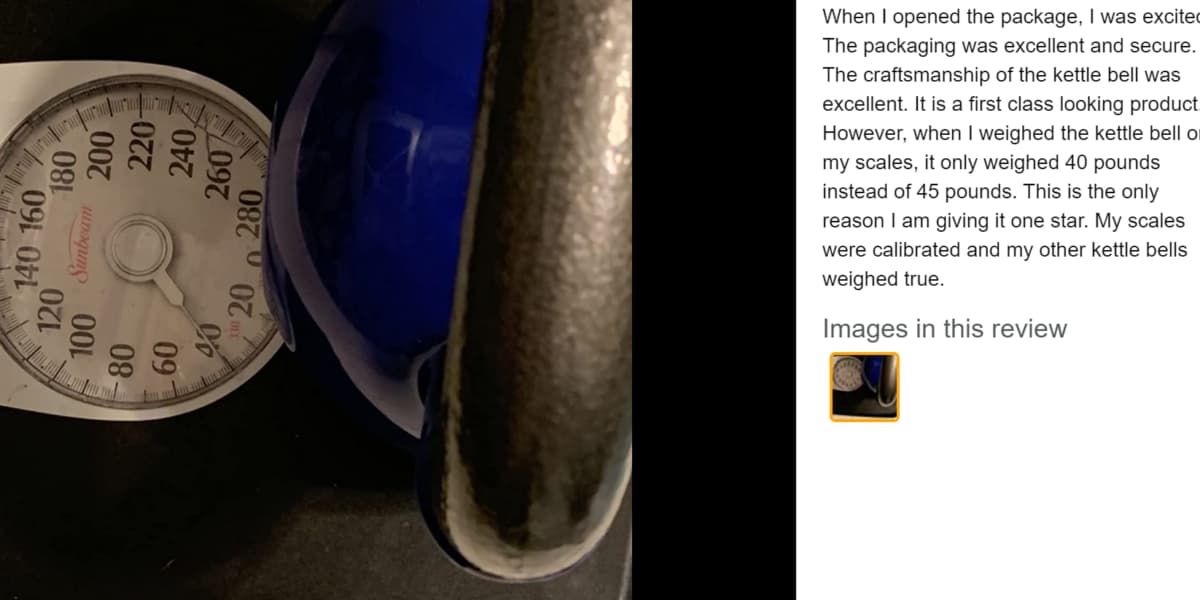

The size of the kettle body of each specification of the competition kettlebell is the same size. They achieve different weights by adjusting the material and quantity of the internal filling. It can be judged as a defective product.

The welded part of the handle needs to check whether the weld scar is polished clean, and the bottom surface is flat is the basic requirement

Here are the handle issues with competing kettlebells from competitors found on Amazon:

C. Rubber coated kettlebells

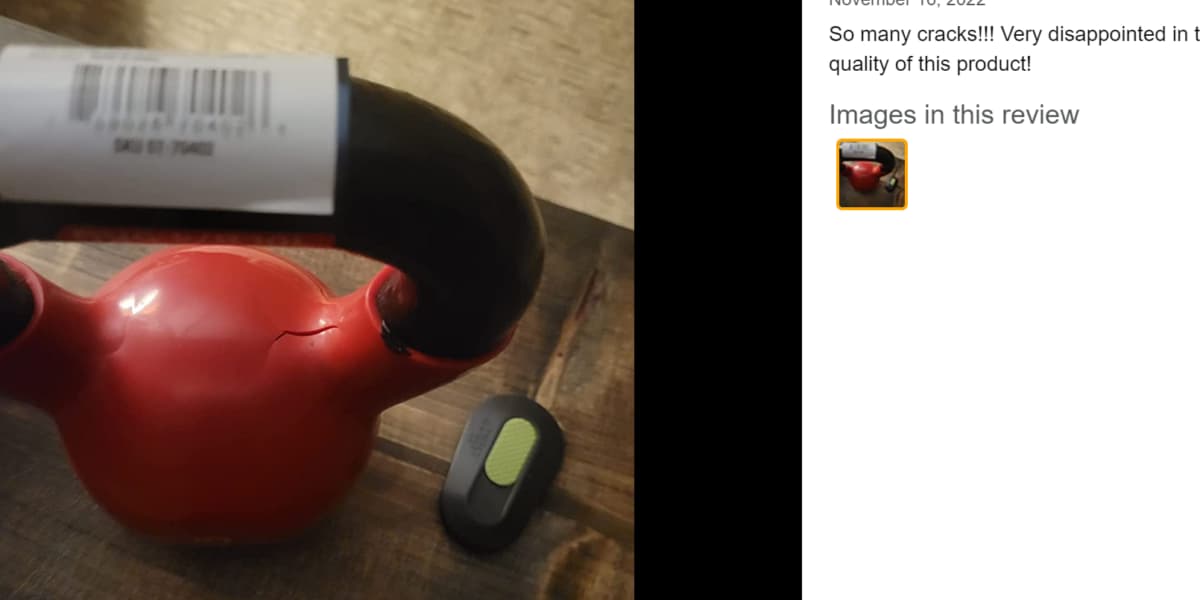

Look at the surface, dimensional weight, drop test, stickers, handle welds, all seams, smell, hardness, etc.

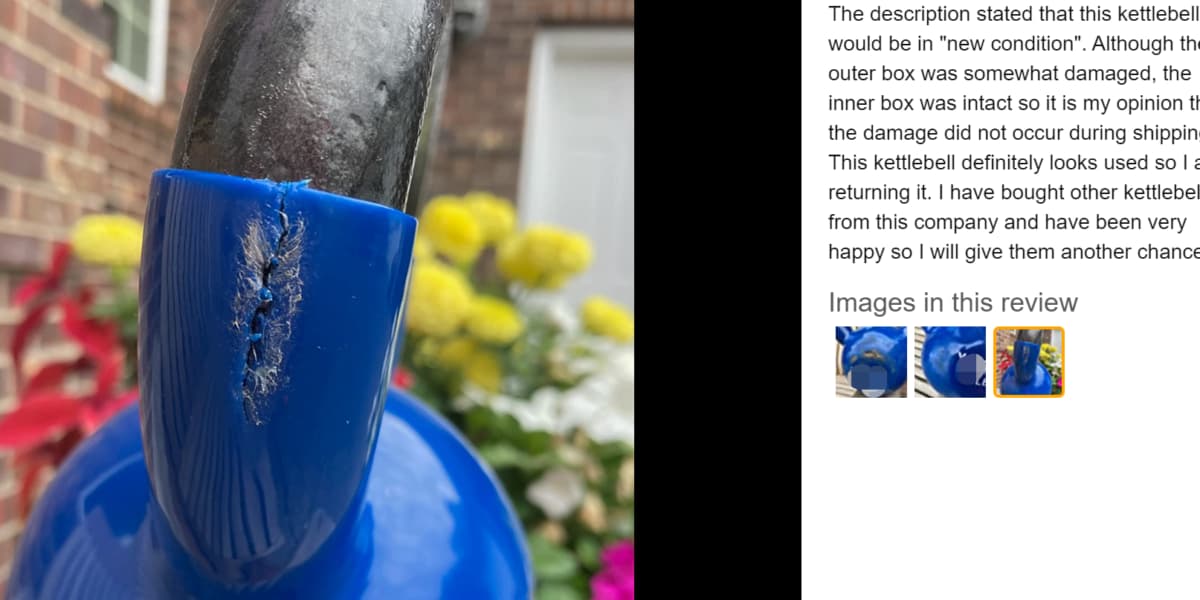

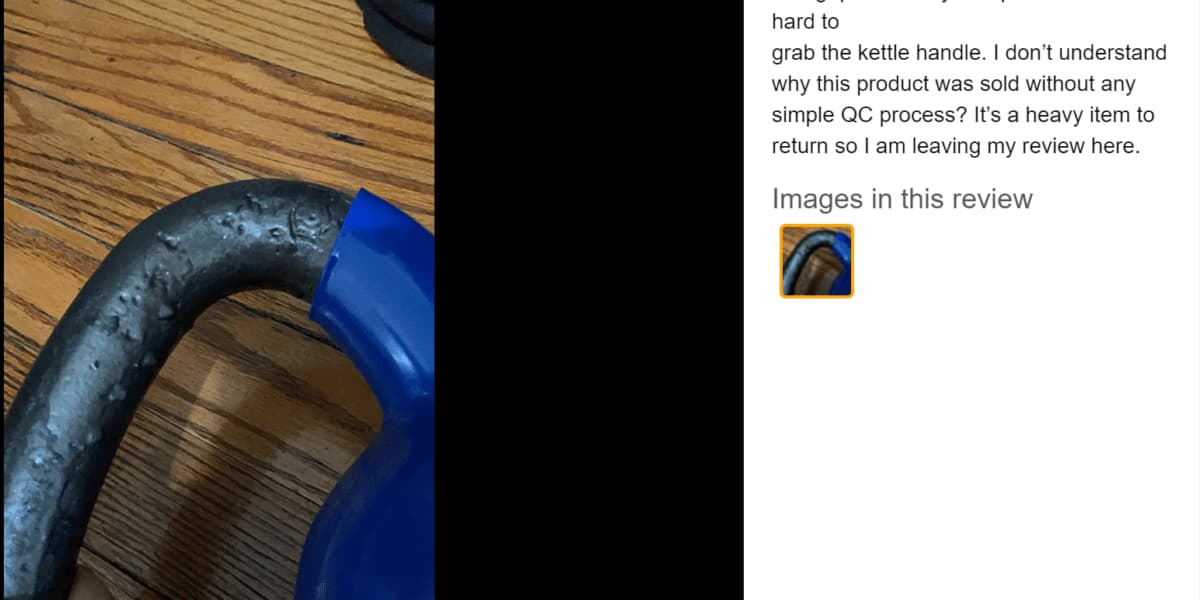

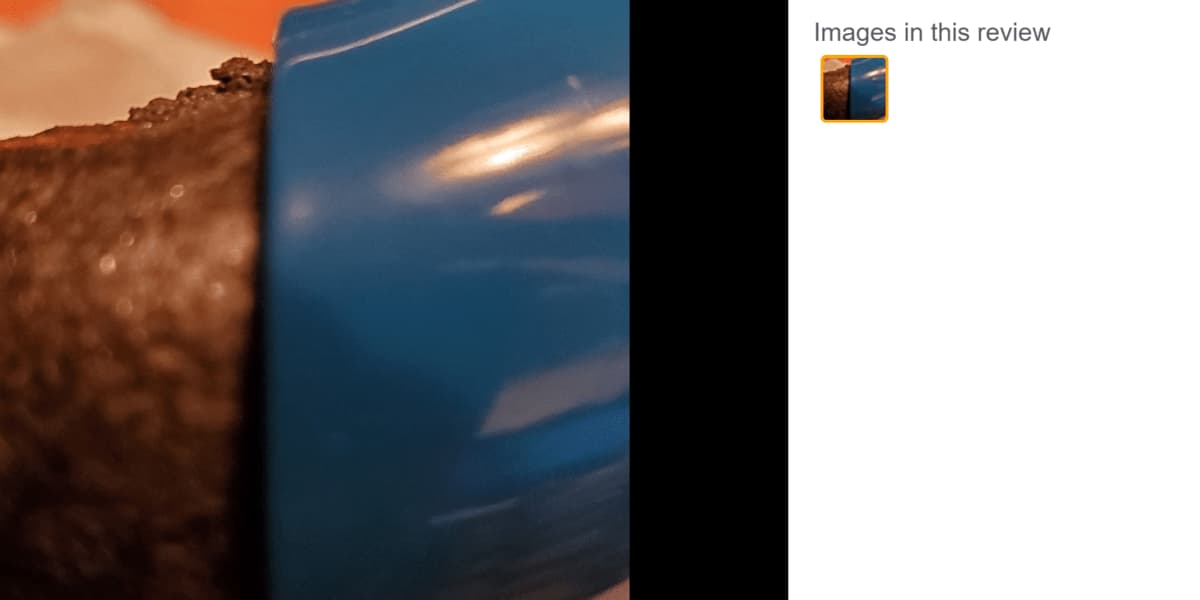

The point to pay attention to for rubber coated kettlebells is that at the joint between the handle and the rubberized layer, the rubberized layer is prone to detachment, which is usually caused by improper mold design or rubber temperature control.

D. Dip plastic kettlebell

Look at surface, dimensional weight, drop test, stickers, handle welds, all seams, smell, hardness, etc.

The following is the weight problem of the dipped kettlebells produced by the same industry found on the Amazon website:

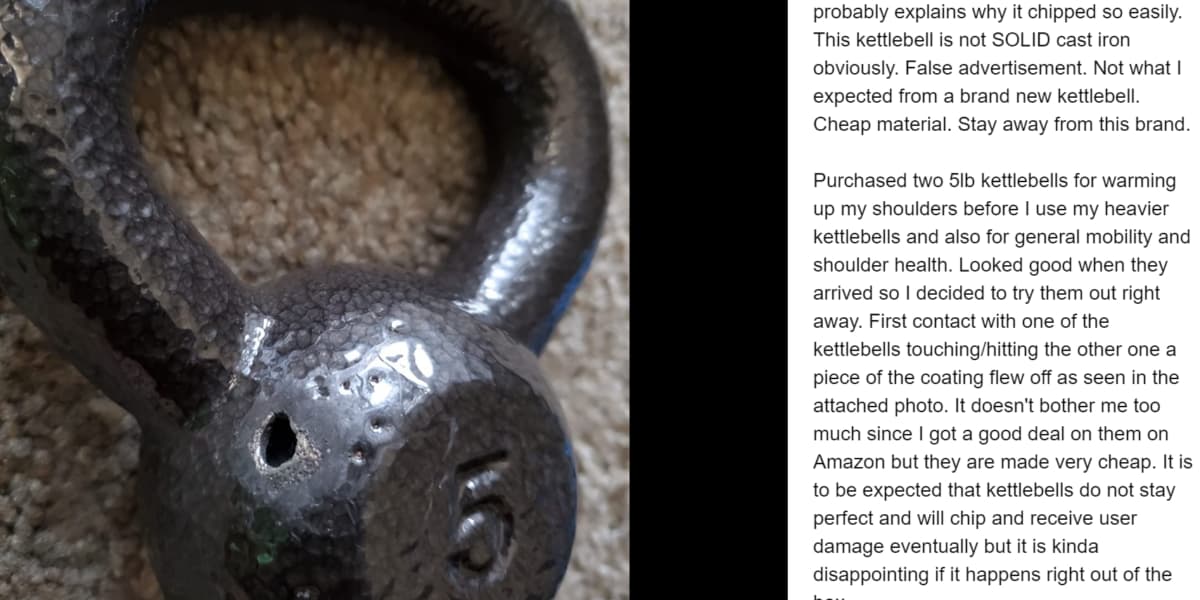

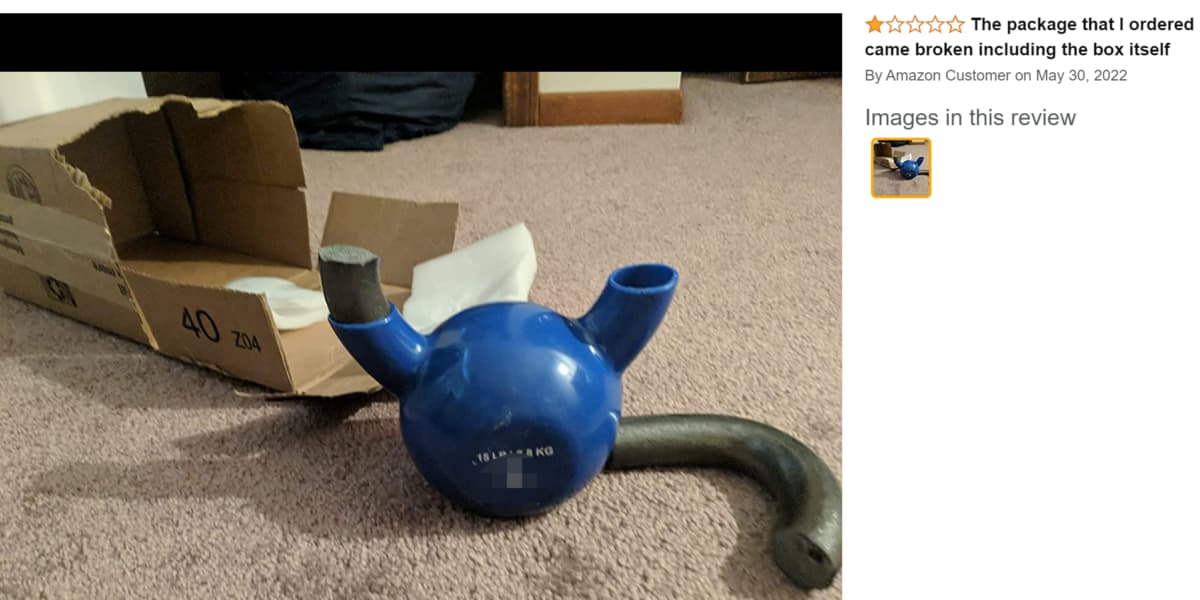

he following are the strength issues of the dipped kettlebells produced by peers found on the Amazon website:

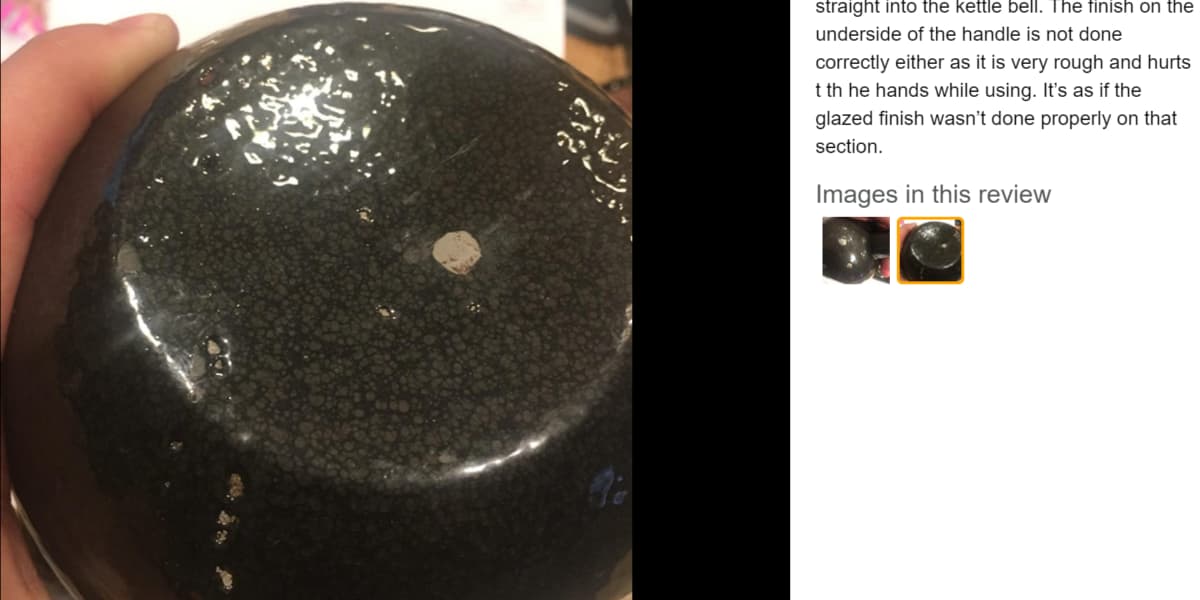

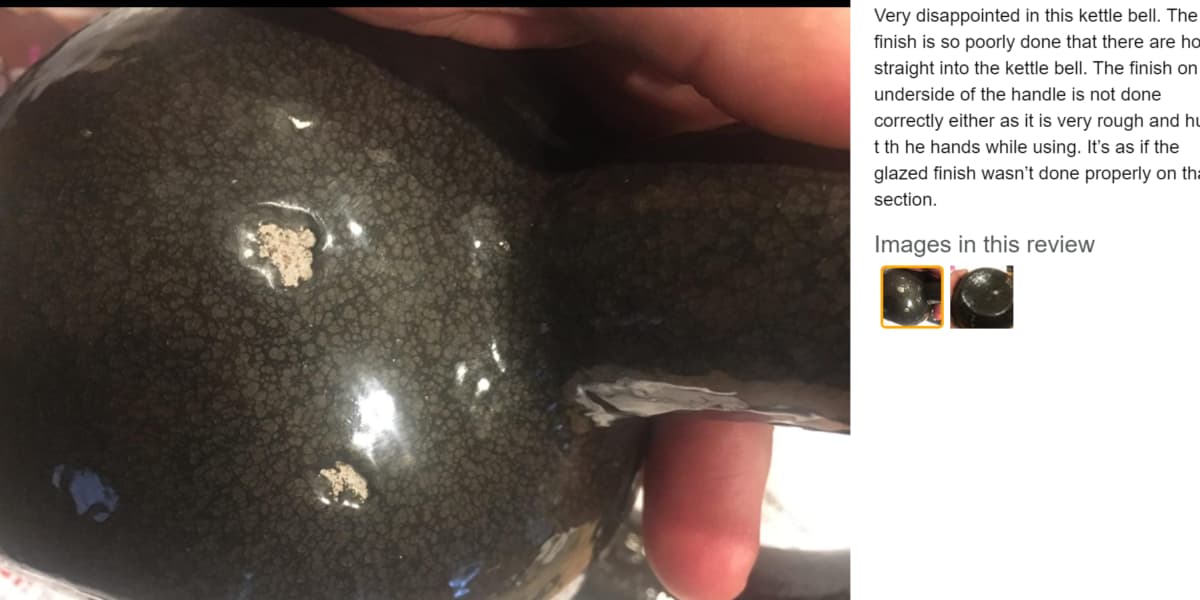

Here are the superficial issues with vinyl-coated kettlebells from peers found on Amazon:

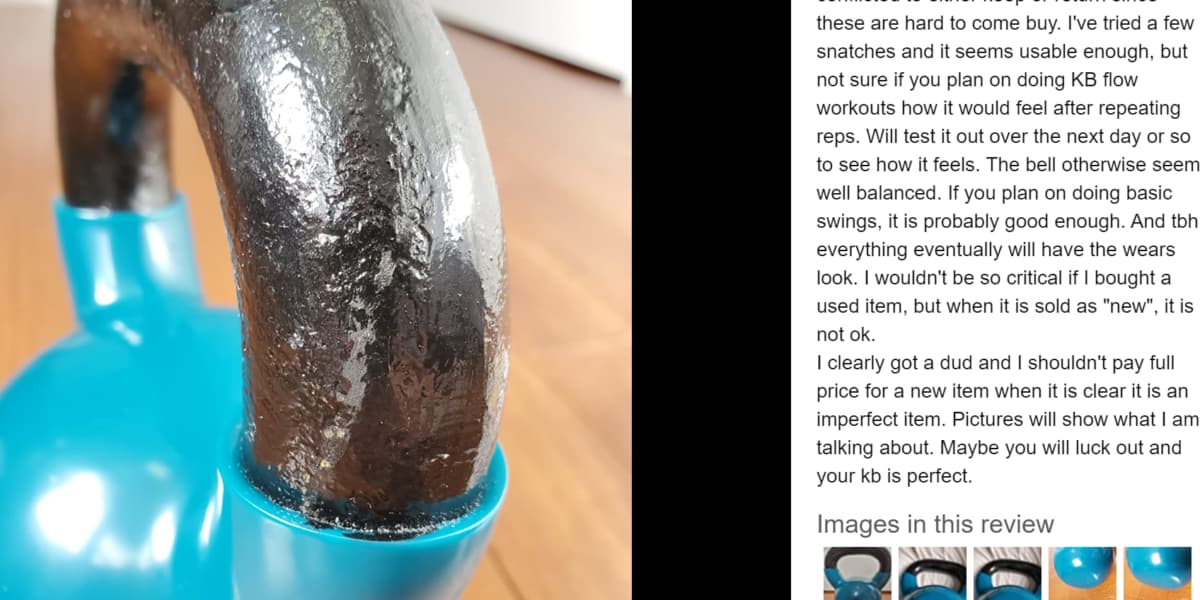

Similar to plastic-coated kettlebells, special attention must be paid to the connection between the plastic dipping and the handle. In addition, the handles of plastic dipping dumbbells are generally cast iron and painted, and the surface quality is relatively rough. Please carefully check whether the surface is smooth and whether there is paint falling off.

Following is the handle problem of the dipped kettlebell produced by the same industry found on the Amazon website:

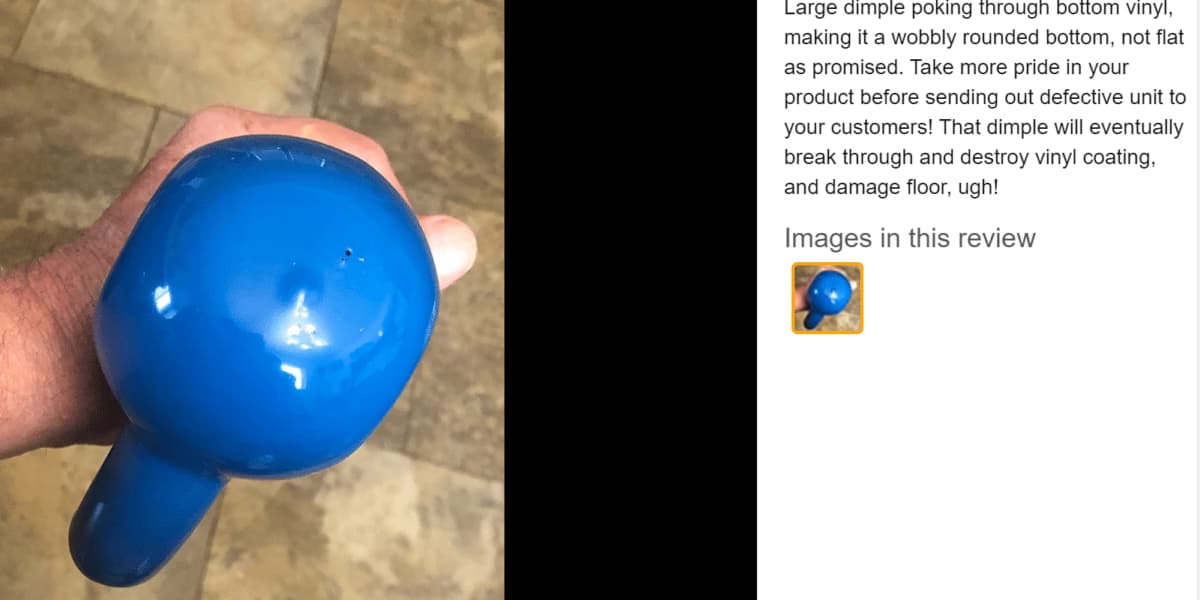

The following is the flatness of the bottom surface of the dipped kettlebells produced by the same industry found on the Amazon website:

E. PU kettlebell

Look at surface, dimensional weight, drop test, stickers, handle welds, all seams, smell, hardness, etc.

The wear resistance and drop resistance of PU material are even better. For high-end commercial application scenarios, under the premise that the detection method remains unchanged, it should be able to withstand higher requirements.